The Automotive Industry’s Peak Employment: America’s Manufacturing Powerhouse

The automotive industry’s historic impact on American employment

The automotive industry has longsighted been considered a cornerstone of American manufacturing and economic strength. At its zenith, this sector employs a remarkable portion of the American workforce, create an extensive network of jobs that extend far beyond assembly lines into numerous related industries.

Source: automobileindustryakunui.blogspot.com

Peak employment in the auto industry

During its height in the late 1970s, around 1 in 10 American jobs was connected to the automotive industry in some capacity. Thitranslateste to approximately 10 % of the entire u.s. workforce beiemployedloy either direct by automakers or in related sectors that support vehicle production, distribution, and maintenance.

The direct manufacturing workforce solo peak at nearly 1.3 million workers employ by auto manufacturers. Nonetheless, the industry’s true employment impact was practically larger when consider the entire ecosystem.

The Detroit era

The industry’s dominance was near visible in Detroit, which earn the nickname” motor city ” s it become the global center of automotive manufacturing. During the industry’s golden age, metropolitan deDetroitee most 40 % of its workforce employ in automotive relate positions.

The big three automakers — General Motors, ford, and Chrysler — jointly employ hundreds of thousands of workers at their peak. General Motors exclusively formerly employ more than 600,000 people in the United States, make it the largest private employer in the world for a time.

The automotive employment ecosystem

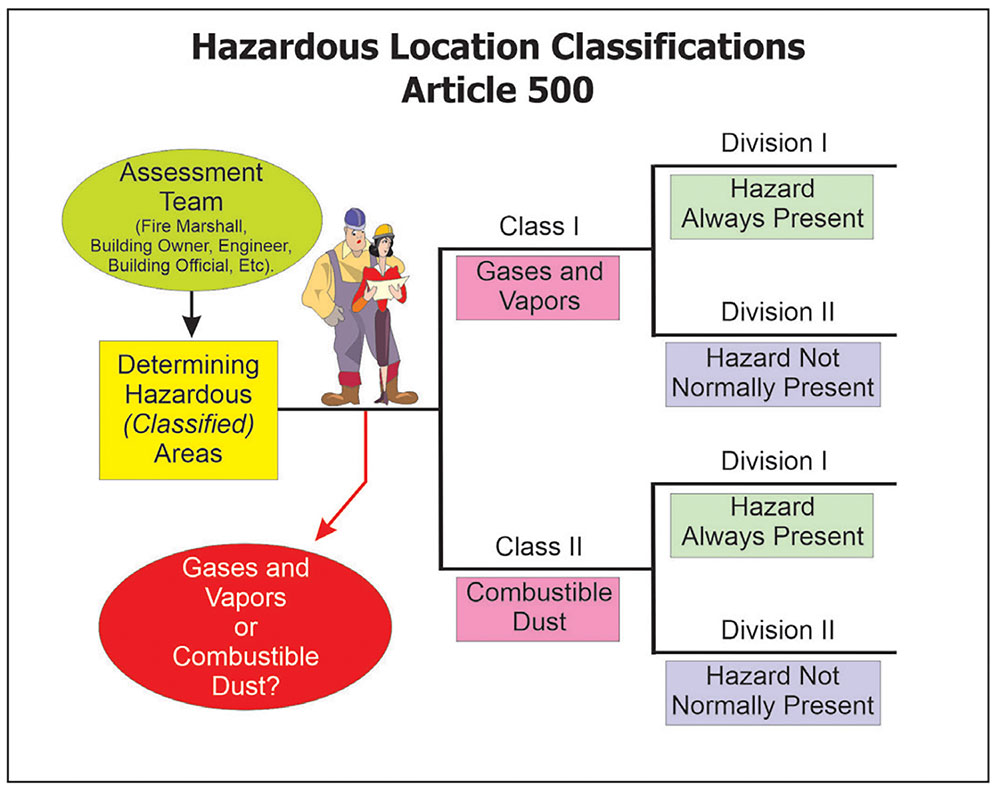

What make the automotive industry such a powerful employment engine was its extensive ecosystem of related businesses. The full employment impact includes:

Primary manufacturing

This category includes workers direct employ by automakers to assemble vehicles. At its peak, this sectoremploysy roughly 1.3 millioAmericansns work in assembly plants across the country.

Parts and components manufacturing

The supply chain for automotive production was vast, with thousands of companies produce everything from tires and glass to electrical systems and interior components. This sector employ roughly 850,000 workers during the industry’s height.

These suppliers range from large corporations produce major components to smaller specialized manufacturers create specific parts. Each vehicle contain thousands of parts, create a complex supply network that generate substantial employment.

Raw materials and processing

Automotive production consume enormous quantities of steel, aluminum, rubber, plastic, and other materials. The mining, refining, and processing industries that supply these materials count a significant portion of their workforce arsenic indirectly employ by automotive demand.

Steel mills in Pennsylvania, Ohio, and Indiana rely intemperately on automotive contracts, with some dedicate more than half their production to meet the needs of vehicle manufacturers.

Dealerships and sales

The retail side of the automotive industry employ hundreds of thousands of salespeople, finance specialists, and administrative staff. At the industry’s peak, roughly 700,000 Americans work in automotive sales.

Maintenance and repair

Auto mechanics, body shops, parts stores, and service centers form another significant employment sector. This area employ approximately 1 million workers during the industry’s height.

Transportation and logistics

Move raw materials to factories and finish vehicles to dealerships require an extensive transportation network. Rail workers, truck drivers, and logistics specialists form another segment of auto relate employment.

Fuel and service stations

Gas stations and service centers employ hundreds of thousands of workers whose jobs exist mainly to support automobile usage.

Infrastructure development

Road construction, highway systems, and parking facilities employ workers whose jobs were forthwith tie to the proliferation of automobiles.

Regional impact of automotive employment

The concentration of automotive employment varies importantly by region, with thMidwestst experience the near profound impact. During the industry’s peak:

The Midwest manufacturing belt

Michigan, Ohio, Indiana, and Illinois form the core of automotive manufacturing. In some communities within these states, more than 50 % of all jobs were connected to the automotive industry either direct or indirectly.

Michigan was especially dependent on the industry, with roughly 20 % of its entire workforce employ in automotive relate positions during the sector’s height.

Southern expansion

As the industry evolve, states like Kentucky, Tennessee, Alabama, and South Carolina become important automotive manufacturing centers, especially as foreign automakers establish u.s. operations.

The multiplier effect

Economists have studied the employment multiplier effect of automotive manufacturing jobs, find that each direct job in auto assembly support between 7 and 10 additional jobs throughout the economy. This multiplier effecoccursur through:

Supply chain jobs

Each assembly plant job support some 3 5 supplier jobs.

Community service jobs

The spending power of automotive workers support local restaurants, retail, healthcare, education, and other service industries.

Tax base effects

The industry generate substantial tax revenue that fund public sector employment in automotive heavy communities.

The decline from peak employment

Several factors have contributed to the decline in automotive employment from its historic peak:

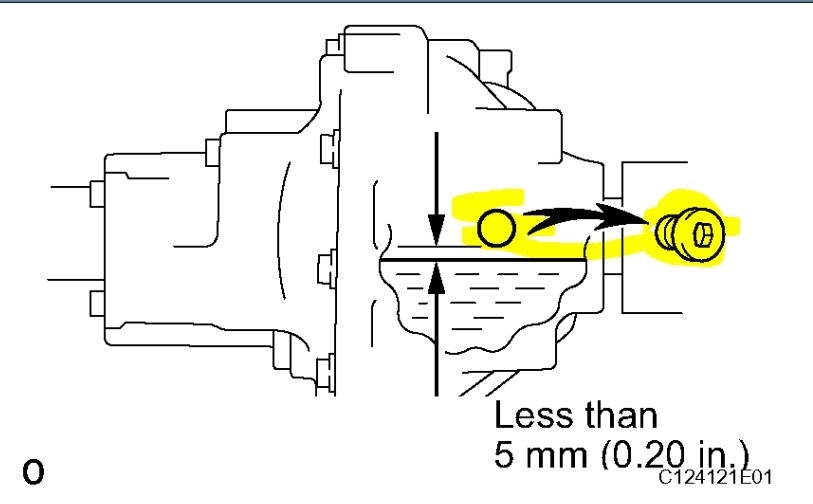

Automation and productivity improvements

Modern automotive plants can produce more vehicles with fewer workers. Robotics, computer aid design, and advanced manufacturing processes have dramatically increased productivity while reduce labor requirements.

A vehicle that erstwhile require 30 labor hours to assemble might instantly require fewer than 15 hours, efficaciously halve the workforce need per unit produce.

Globalization

The shift toward global supply chains has moved some production abroad. Components that were formerlymanufacturede domestically are nowadays oftentimes import.

Industry consolidation

Mergers and acquisitions have eliminated duplicate positions and streamlined operations. The supplier base has likewiseconsolidatede, create larger but fewer employers.

Market share changes

American automakers have lost significant market share to foreign competitors over the decades, though many foreign manufacturers have established u.s. production facilities.

Current state of automotive employment

Today, the automotive industry remains a significant employer, though at levels substantially below its historic peak. Direct employment in motor vehicle and parts manufacturing presently stand at roughly 1 million workers, represent less than 1 % of the total u.s. workforce.

When include all related industries — sales, repair, transportation, and others — the current percentage of Americans employ in automotive relate work is roughly 4.5 %, less than half of the industry’s peak impact.

The new automotive workforce

The nature of automotive employment has to change importantly. Today’s workforce include more engineers, software developers, and technical specialists than in previous eras. Electric vehicle production require different skills and components than traditional internal combustion engines.

Source: bls.gov

The average automotive worker today is more likely to operate complex machinery, program robots, or analyze production data than to perform repetitive manual assembly tasks.

Future trends in automotive employment

Several emerge trends are reshaped automotive employment:

Electrification

The transition to electric vehicles is created new jobs in battery production, charge infrastructure, and electronics, while potentially reduce jobs in traditional powertrain manufacturing.

Autonomous vehicles

The development of self drive technology is created high skilled jobs in software development, artificial intelligence, and sensors, while potentially threaten employment in driving relate occupations.

Advanced manufacturing

Continue advances in manufacturing technology are likely to air reduce the number of workers need per vehicle produce, while increase the technical skills require.

The lasting legacy

The automotive industry’s impact on American employment extend beyond numbers. It helps create and sustain theAmericann middle class, establish patterns of industrial relations that influence other sectors, and shape communities across the country.

While the industry may ne’er again employ the percentage of American workers it erstwhile does, its historical role in provide millions of substantially pay jobs haleftve an indelible mark onAmericann economic history.

The industry’s evolution continue to reflect broader economic trends — globalization, automation, and the shift from manufacture to service employment — that have transformed thAmericanan labor market over the past several decades.

Conclusion

At its absolute peak, roughly 10 % of American workers were employed in automotive relate industries, make it one of the nearly significant employment sectors iAmericanan economic history. This extensive employment networcreateste a powerful economic engine that helped driAmericancan prosperity throughout much of the 20th century.

While that percentage has decline importantly due to automation, globalization, and change market dynamics, the automotive industry remains an important source of employment and continue to evolve as transportation technology advance. The industry’s transformation mirror the broader changes in theAmericann economy, serve as both a driver and reflection of economic evolution.

Understand this history provide valuable context for current discussions about manufacture employment, technological change, and the future of work in America.

MORE FROM promospotlight.com