Short to Ground in Vehicles: Understanding Electrical Faults

What’s a short to ground in automotive systems?

A short to ground in automotive electrical systems occur when an electrical current find an unintended path to ground. In normal operation, electricity flow from the battery’s positive terminal, through various components, and return to the battery’s negative terminal (ground). When a short circuit to ground happen, the current bypasses the intended pathway and flow direct to ground, oftentimes cause blow fuses, damage components, or electrical fires.

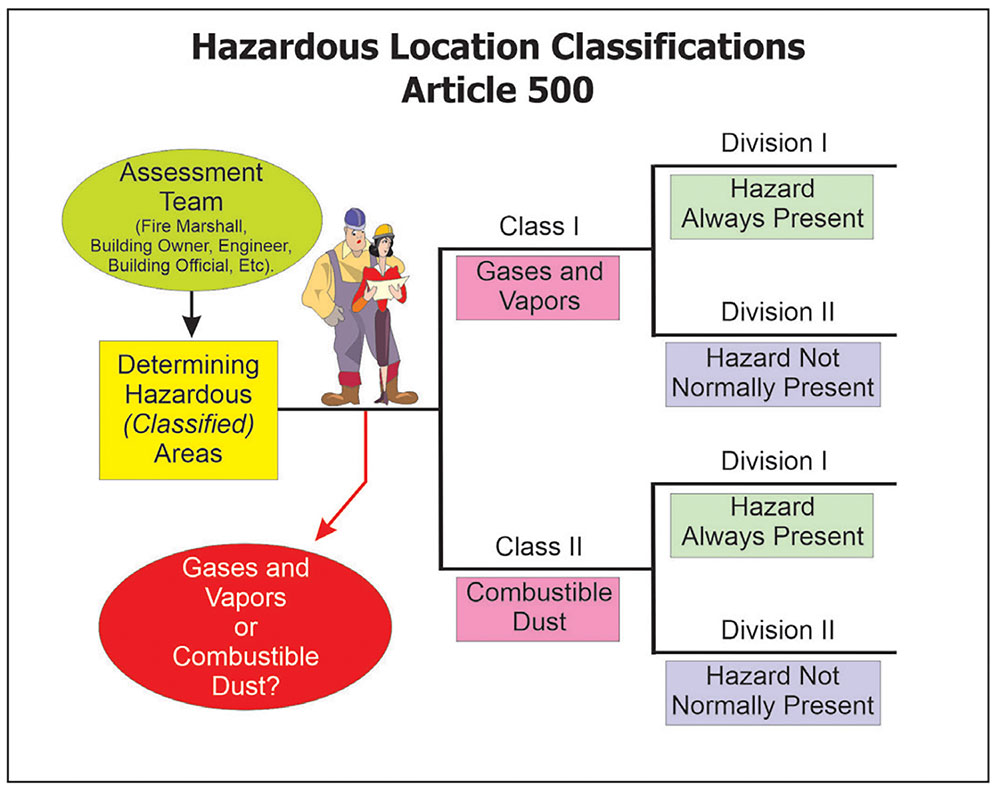

Understand vehicle electrical systems

To comprehend shorts to ground, you need a basic understanding of how automotive electrical systems work:

The basics of automotive circuits

Modern vehicles contain dozens of electrical circuits that power everything from headlights to engine management computers. These circuits consist of:

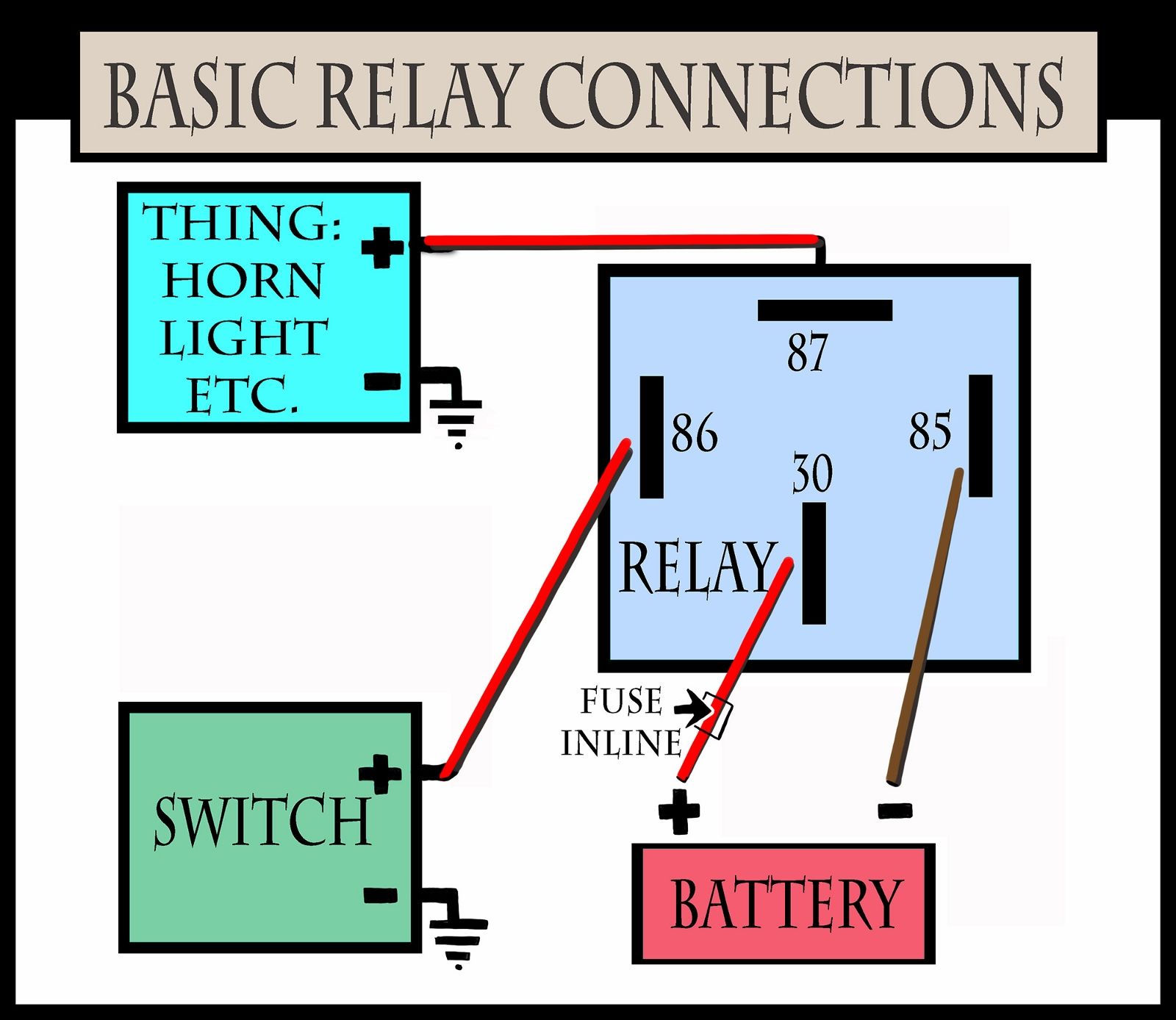

- Power source (typically the battery )

- Conductors (wires )

- Protection devices (fuses and circuit breakers )

- Loads (components that use electricity )

- Switches (to control current flow )

- Ground connections (return path to the battery )

In automotive systems, the vehicle’s metal chassis serve as the ground or negative return path. This design allow manufacturers to use single wires for most circuits instead than run both positive and negative wires everyplace.

The role of ground in vehicle electrical systems

The ground connection in a vehicle provides the return path for electrical current. The negative terminal of the battery connect immediately to the vehicle’s chassis, make the entire metal frame a conductor for complete electrical circuits. This design simplifies wiring butto createe the potential for shorts to ground when insulation fail.

How shorts to ground occur

Shorts to ground typically happen when a wire carry positive voltage make contact with any metal part of the vehicle. This creates a path of least resistance that bypass the intended component.

Common causes of shorts to ground

-

Damage wire insulation:

Worn, chafe, or melt insulation exposes the conductor interior, allow it to contact metal parts. -

Pinched wires:

Wires catch between metal components during repairs or manufacturing can have their insulation compromise. -

Corrosion:

Battery acid, road salt, and moisture can deteriorate wiring and connections, create pathways for shorts. -

Improper installations:

After market accessoriesinstalll falsely may create shorts if wires are route improperly. -

Loose connections:

Vibration can cause connections to loosen over time, potentially create intermittent shorts. -

Water intrusion:

Water enter electrical connectors or control modules can create shorts to ground.

Symptoms of a short to ground

Recognize the signs of a short to ground can help prevent more serious damage:

Source: galvinpower.org

Immediate signs

-

Blown fuse:

The almost common symptom, as fuses are design to protect circuits from excessive current. -

Inoperative components:

Lights, windows, or other electrical components that dead stop work. -

Battery drain:

A short can drain your battery flush when the vehicle is removed. -

Burn smell:

Electrical shorts generate heat and may produce a distinctive burn odor. -

Visible smoke:

In severe cases, you might see smoke come from the wiring harness or components.

Intermittent symptoms

Some shorts to ground occur sole under specific conditions:

-

Components that work inconsistently:

Function exclusively when the vehicle hit bumps or when the engine vibrates at certainrpms. -

Weather dependent issues:

Problems that appear exclusively in rain or high humidity. -

Fuses that blow repeatedly:

Replace a fuse work temporarily, but it blows again shortly afterward.

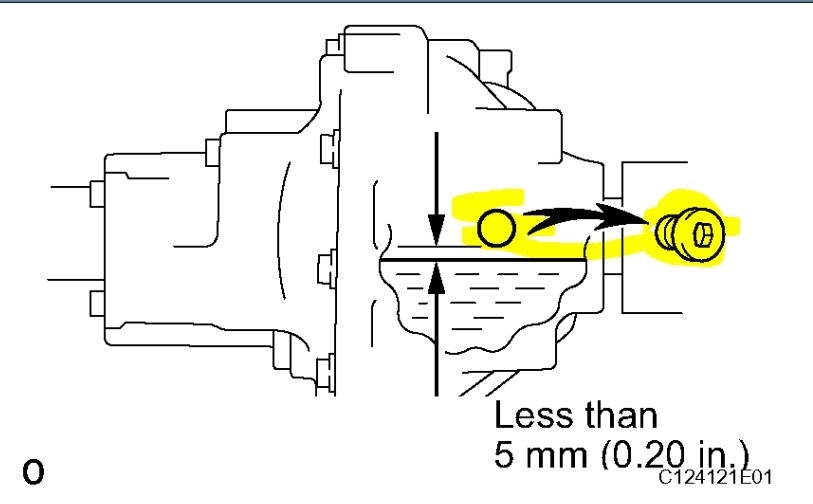

Diagnose a short to ground

Find the exact location of a short can be challenge, but these methods can help:

Tools need

- Digital multimeter (dDMM)

- Test light

- Wiring diagrams for your specific vehicle

- Fuse puller

- Circuit breaker (to substitute for a fuse during testing )

Step-by-step diagnostic process

-

Identify the affected circuit:

Determine which fuse is blow and what components it protects. -

Consult wiring diagrams:

Review the circuit layout to understand all components and wiring paths. -

Visual inspection:

Look for obvious damage along the wiring path, pay special attention to areas where wires pass through metal, near move parts, or are exposed to heat. -

Disconnect components:

Consistently disconnect components in the affected circuit to isolate the short. -

Resistance testing:

Use a multimeter to check for low resistance between the positive wire and ground. -

Voltage drop testing:

Measure voltage drop across various points in the circuit to locate high resistance connections.

Use a multimeter to find shorts

A digital multimeter is your nigh valuable tool for find shorts:

- Disconnect the battery negative terminal for safety.

- Set your multimeter to measure ohms (resistance )

- Connect one probe to the positive terminal of the suspect circuit and the other to a good ground point.

- A reading of rattling low resistance (near zero ohms )indicate a short to ground.

- To pinpoint the location, disconnect components or sections of wire one at a time while monitor the resistance reading.

Common locations for shorts to ground

While shorts can occur anyplace, certain areas are more prone to problems:

High risk areas

-

Engine compartment:

Heat, vibration, and oil / fluid exposure make this a common location for insulation failure. -

Door jambs:

Wires run between the body and doors can become pinch or chafe. -

Underbody:

Wires expose to road debris, moisture, and salt are vulnerable. -

Battery area:

Corrosion from battery acid can damage nearby wiring. -

Recent repair areas:

Wiring disturb during repairs may not have been decent secure.

Component specific shorts

-

Alternator:

Internal shorts can cause charge system issues. -

Starter motor:

Wear insulation in the starter can cause shorts when crank. -

Fuel pump:

Wiring expose to fuel can deteriorate over time. -

Lighting systems:

Moisture intrusion in light housings is a common cause of shorts. -

HVAC blower motors:

Frequently develop shorts as they age.

Repair shorts to ground

Once you’ve located the short, proper repair is essential to prevent recurrence:

Repair methods

-

Replace damage wiring:

Don’t merely tape over damage insulation; replace the wire section or entire harness if necessary. -

Use proper splicing techniques:

For wire repairs, use heat shrink connectors or solder and heat shrink tubing. -

Secure wiring:

Use wire loom, clips, and ties to prevent wires from contact move parts or hot surfaces. -

Apply dielectric grease:

Use this in connectors to prevent moisture intrusion and corrosion. -

Replace corrode terminals:

Don’t try to clean badly corrode terminals; replace them.

Professional vs. DIY repair

Consider these factors when decide whether to repair a short yourself:

-

Complexity:

Modern vehicles have sophisticated electronics that may require specialized tools and knowledge. -

Accessibility:

Some shorts occur in areas difficult to reach without disassemble multiple components. -

Safety:

Improper repairs can create fire hazards or damage expensive control modules. -

Warranty:

DIY repairs might void your vehicle’s warranty.

For simple shorts in accessible areas, DIY repair can save money. For complex issues, particularly in newer vehicles with can bus networks and multiple computers, professional diagnosis and repair is oftentimes the wiser choice.

Prevent shorts to ground

An ounce of prevention is worth a pound of cure, specially with electrical systems:

Maintenance practices

-

Regular inspections:

Sporadically check visible wiring for damage, particularly after drive in harsh conditions. -

Keep battery connections clean:

Corrosion can spread to nearby wiring. -

Address water leaks quickly:

Water intrusion is a major cause of electrical problems. -

Use fuse taps for accessories:

When add after market equipment, use proper fuse taps instead than splice into exist wiring. -

Follow proper jump start procedures:

Incorrect jump-starting can cause damaging power surges.

Best practices for add accessories

Many shorts occur after installafter markett equipment:

- Use a dedicated fuse for each new accessory.

- Route wires outside from move parts, heat sources, and sharp edges.

- Use grommets when pass wires through metal panels.

- Connect grounds to clean, paint free metal surfaces.

- Use decent sized wire for the current load.

- Consider a professional installation for complex systems like remote starters or high-pitched power audio.

The impact of shorts to ground

Ignore electrical shorts can lead to serious consequences:

Potential damage

-

Fire risk:

Shorts generate heat that can ignite surround materials. -

Component damage:

Excessive current can destroy expensive electronic modules. -

Battery failure:

Constant shorts drain and damage batteries. -

Strand:

Electrical failures can leave you strand if they affect start or fuel delivery systems. -

Corrosion propagation:

Electrical current can accelerate corrosion through electrolysis.

Safety implications

Beyond vehicle damage, shorts can create safety hazards:

Source: digitalgadgetwave.com

- Loss of lighting while drive

- Failure of safety systems like abs or airbags

- Unexpected electrical fires

- Disabled communications (if phone charging systems are affect )

Modern vehicles and shorts to ground

As vehicles become more electronically sophisticated, the nature of electrical problems change:

Complex electronic systems

Modern vehicles may have 50 + computer modules communicate over multiple networks. This complexity mean:

- Traditional shorts notwithstanding occur, but diagnosis is more complex

- Control modules have more sophisticated short circuit protection

- Shorts can cause communication network failures affect multiple systems

- Specialized scan tools may be need to identify affected circuits

High voltage systems in hybrid and electric vehicles

Hybrid and electric vehicles present unique challenges:

- High voltage systems (typically 200 800 volts )require specialized safety precautions

- These vehicles have isolation monitoring systems to detect ground faults

- Ne’er attempt DIY repairs on high voltage components

- Regular conventional 12v systems in these vehicles are more complex

Conclusion

Shorts to ground are among the about common and frustrating automotive electrical problems. Understand what cause them, how to diagnose them, and how to repair them decent can save you time, money, and potential safety hazards.

While simple shorts can be address by DIY enthusiasts with basic electrical knowledge, complex issues in modern vehicles oftentimes warrant professional attention. Remember that proper diagnosis is key — haphazardly replace parts seldom solve electrical problems efficaciously.

By maintain your vehicle’s electrical system and address problems quickly, you can avoid the cascade issues that frequently result from ignore electrical faults. When in doubt, consult your vehicle’s service manual or seek professional assistance, specially for safety critical systems or when deal with unfamiliar technology.

MORE FROM promospotlight.com