How Geopolitics Is Reshaping Automotive Supply Chains: Risks, Strategies, and Solutions

Photo by Diko OnTop on Unsplash

Understanding Geopolitics and Automotive Supply Chains

The automotive industry is known for its complex, globally distributed supply chains that connect manufacturers, suppliers, logistics providers, and raw material producers across continents. In recent years, the impact of geopolitics on automotive supply chains has grown more pronounced, creating both new challenges and opportunities for businesses in this sector. This article explores the key ways that geopolitical events, trade policies, and international tensions are reshaping how automotive companies source, build, and deliver vehicles-and provides actionable guidance for navigating this evolving landscape.

The Growing Influence of Geopolitical Tensions

Geopolitical factors such as trade wars, tariff escalations, and international conflicts have become central concerns for automotive industry leaders. According to a recent industry outlook, nearly half of automotive supply chain leaders cite geopolitical tensions as a significant headwind, particularly outside of Germany [1] . These tensions manifest in several ways:

- Tariff Volatility: The United States has introduced steep import tariffs-such as a 25% rate on certain auto imports-which led some automakers to pause and reassess their sourcing and production strategies. For example, Hyundai shifted part of its Tucson SUV production from Mexico to Alabama, while Honda redirected Civic manufacturing to Indiana [1] .

- Regional Trade Barriers: Trade disputes can trigger rapid regulatory changes. The US, for instance, recently imposed 50% tariffs on steel and aluminum imports from India and extended similar rates to hundreds of other items, directly affecting the cost and availability of automotive components [4] .

- Supply Chain Uncertainty: Automakers report that forward planning is now constrained by shifting policy timelines and the unpredictability of international relations. This uncertainty often leads to increased costs, production delays, and the need for contingency planning [2] .

Real-World Examples of Geopolitical Disruption

Several recent events illustrate the real-world impact of geopolitics on automotive supply chains:

- After the US announced new tariffs, Ford increased prices on Mexico-built models, while General Motors projected a $4-5 billion tariff impact in 2025. GM responded by investing $4 billion to reshore production of certain models, exemplifying how companies adapt to protect their supply chains [1] .

- GM plans to continue importing electric vehicle batteries from China’s CATL despite a 30% tariff, highlighting the difficulty of fully localizing complex supply chains for high-tech components [4] .

- Ongoing wars have disrupted routes for critical raw materials like steel and affected labor availability, causing delays and forcing companies to find alternative suppliers or logistics routes [2] .

Challenges Intensified by Geopolitical Volatility

Automotive supply chains are especially vulnerable to geopolitical shifts due to their long production cycles, high regulatory requirements, and dependence on just-in-time manufacturing. Key challenges include:

- Rising Production Costs: Tariffs and trade restrictions increase the cost of imported parts and materials, forcing manufacturers to either absorb higher expenses or pass them on to consumers [1] .

- Delays and Bottlenecks: Shifts in trade policy can mean longer lead times for essential components, disrupting production schedules and reducing inventory flexibility [5] .

- Regulatory Complexity: Companies must navigate an ever-changing web of international regulations, certifications, and compliance requirements-each of which may differ by country or region [3] .

Strategies for Building Resilient Automotive Supply Chains

To mitigate geopolitical risks, automotive companies are adopting several proactive strategies:

1. Diversification and Nearshoring

Diversifying suppliers and production locations reduces reliance on any single country or region. Nearshoring-relocating production closer to key markets-can limit exposure to cross-border disruptions. For example, Hyundai and Honda’s moves to shift manufacturing to the US illustrate the benefits of regional flexibility [1] .

Implementation Guidance: To begin diversifying your supply chain, conduct a comprehensive supplier risk assessment. Identify critical parts sourced from high-risk regions and seek alternative suppliers where feasible. Companies can also collaborate with regional development agencies-search for ‘regional supply chain initiatives’ in your area for support programs.

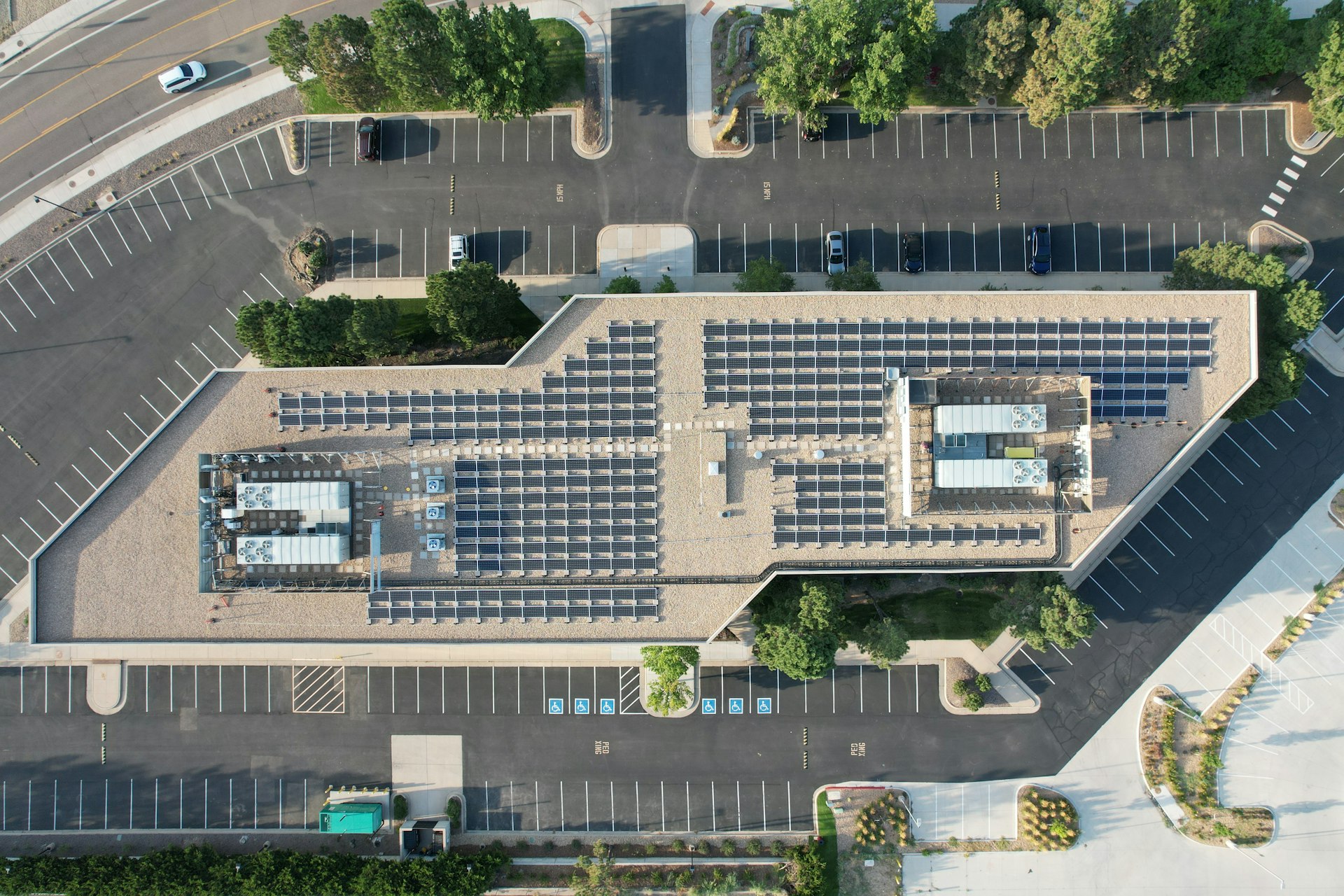

Photo by Shot On DJI on Unsplash

2. Enhanced Supply Chain Visibility

Advanced digital tools and real-time data platforms provide end-to-end visibility across the supply chain. This helps companies track shipments, anticipate disruptions, and optimize inventory management. Predictive analytics can offer early warning signals for potential geopolitical or logistical issues [5] .

Implementation Guidance: Evaluate digital logistics platforms and request demonstrations from leading providers. When choosing a platform, prioritize solutions that support shipment tracking, predictive analytics, and multi-modal integration. Consider searching for ‘automotive supply chain visibility solutions’ to compare vendors and features.

3. Scenario Planning and Contingency Strategies

Scenario planning allows companies to model the potential impacts of geopolitical events, such as new tariffs or supply disruptions, and develop contingency plans. This may involve stockpiling critical parts, securing backup logistics routes, or creating flexible production schedules [3] .

Implementation Guidance: Assemble a cross-functional team to map your current supply chain and brainstorm plausible geopolitical scenarios. Assign roles and responsibilities for rapid response. Many organizations also use simulation software-search for ‘supply chain scenario planning tools’ for options that fit your scale and budget.

Accessing Support and Resources

While no single resource can guarantee protection from geopolitical disruption, automotive companies can leverage several support mechanisms:

- Industry Associations: Organizations such as the Automotive Industry Action Group (AIAG) and the Original Equipment Suppliers Association (OESA) offer supply chain risk management resources and guidance. You can join these associations or participate in their working groups for up-to-date best practices.

- Government Trade Agencies: National trade and commerce departments provide intelligence on regulatory changes, trade agreements, and exporter/importer assistance. To locate relevant programs, search for your country’s trade ministry or regional economic development office.

- Consulting Firms: Many global consultancies, including KPMG and Deloitte, publish regular reports on industry risk trends and offer tailored advisory services. Engage with these firms for bespoke supply chain assessments and risk mitigation planning.

For company-specific support, reach out to your logistics providers to discuss how they monitor geopolitical risks and what contingency plans they have in place. If you’re seeking government incentives for reshoring or supply chain investment, contact your local economic development agency or search for ‘supply chain investment grants’ in your jurisdiction.

Key Takeaways and Next Steps

Geopolitics will remain a defining factor in the automotive supply chain landscape. By enhancing visibility, diversifying suppliers, and investing in scenario planning, companies can build resilience and reduce vulnerability to external shocks. For ongoing success, regularly monitor industry reports, participate in professional networks, and stay informed of regulatory changes in your key markets. Remember: proactive risk management is essential in an era of uncertainty.

References

- [1] Automotive Logistics (2025). Automotive supply chains in flux: 2025 outlook and trends.

- [2] Boise State University (2025). The U.S. Automotive Industry Supply Chain: Challenges and Transformations.

- [3] KPMG (2025). Top geopolitical risks 2025: Industrial Manufacturing insights.

- [4] Automotive Logistics (2025). Regional tariffs, trade deals, and what they mean for automotive logistics and supply chains.

- [5] Supply Chain Brain (2025). Building Resilient Automotive Supply Chains in 2025.

MORE FROM promospotlight.com