Grade 8 Bolts in Automotive Applications: Essential Knowledge for High-Strength Fasteners

Understand grade 8 bolts in automotive applications

When it comes to automotive fasteners, grade 8 bolts stand out as some of the well-nigh important components in vehicle construction and repair. These high strength fasteners play a critical role in ensure the structural integrity and safety of automobiles under extreme conditions. From engine assembly to suspension components, grade 8 bolts are specified by manufacturers for applications where failure is not an option.

Source: mungfali.com

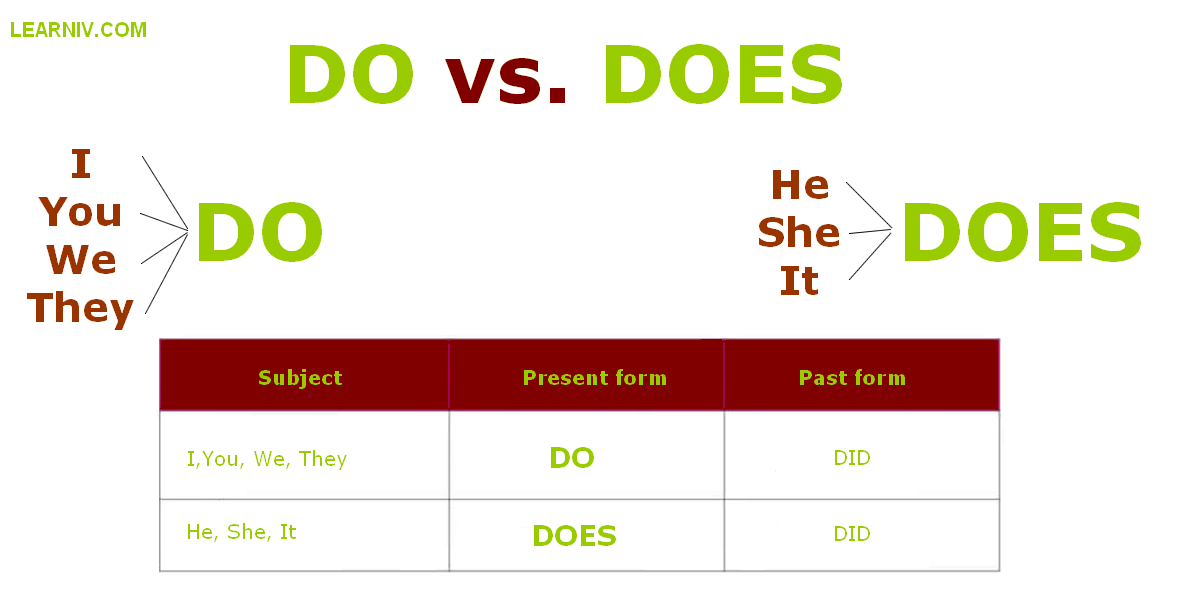

What make a bolt grade 8?

Grade 8 bolts are defined by their material composition and heat treatment process, which give them superior strength characteristics compare to lower grade fasteners. These bolts are typicallymadee from medium carbon alloy steel that has beenquenchedh and temper to achieve specific mechanical properties.

The key specifications that define grade 8 bolts include:

- Tensile strength: minimum 150,000 psi

- Proof load: 120,000 psi

- Hardness: 33 39 HRC (rRockwellc scale )

- Material: medium carbon alloy steel (typically 4140, 4142, or 4340 )

Identification features of grade 8 bolts

Automotive technicians and enthusiasts need to quickly identify bolt grades during maintenance and repair work. Grade 8 bolts feature distinctive markings that make them easy recognizable:

- Six equally space radial lines on the bolt head

- Much finish in yellow zinc for corrosion resistance

- SAE j429 standard mark system

These markings serve as a quick visual reference to ensure the correct fastener is being use for critical applications. Use a lower grade bolt in place of a specify grade 8 could lead to catastrophic failure under load.

Common automotive applications for grade 8 bolts

Grade 8 bolts are specified for numerous high stress applications throughout a vehicle. Understand where these fasteners are require is essential for proper maintenance and repair work.

Engine components

The engine bay contain several critical applications for grade 8 bolts:

- Cylinder head bolts

- Main bearing cap bolts

- Connect rod bolts

- Flywheel bolts

- Harmonic balancer bolts

These components experience extreme forces, temperature fluctuations, and vibration. The high tensile strength of grade 8 bolts helps maintain proper clamp force under these demand conditions.

Suspension and chassis

Vehicle suspension and chassis components rely on grade 8 bolts for safety critical connections:

- Control arm mount bolts

- Strut tower bolts

- Steer component fasteners

- Shock absorber mount hardware

- Subframe mount bolts

These components must withstand road shock, corner forces, and constant vibration while maintain precise alignment. Grade 8 bolts provide the necessary strength and resistance to loosen under these conditions.

Drivetrain applications

The drivetrain transfers power from the engine to the wheels, create substantial torque loads that require high strength fasteners:

- Transmission mount bolts

- Differential cover bolts

- Driveshaft couple bolts

- Axle flange bolts

- Clutch pressure plate bolts

Failure in these areas could lead to immediate loss of power or control, make the use of proper grade 8 hardware essential for vehicle safety.

Torque specifications and installation considerations

Proper installation of grade 8 bolts is fair equally important as use the correct grade. Torque specifications are cautiously calculate by automotive engineers to achieve optimal clamp force without exceed the bolt’s elastic limit.

Torque specifications

Torque values for grade 8 bolts vary base on size, thread pitch, and application. Invariably refer to the vehicle manufacturer’s service manual for specific torque values. As a general reference, Hera are typical torque values for grade 8 bolts with standard threads:

- 1/4 ” 20: 12 ft lbs

- 5/16 ” 18: 25 ft lbs

- 3/8 ” 16: 45 ft lbs

- 7/16 ” 14: 70 ft lbs

- 1/2 ” 13: 110 ft lbs

- 9/16 ” 12: 150 ft lbs

- 5/8 ” 11: 220 ft lbs

These values assume clean, dry threads. When lubricants or thread lockers are use, torque specifications must be adjusted consequently.

Installation best practices

Proper installation techniques ensure grade 8 bolts perform as intend:

- Clean threads exhaustively before installation

- Use a calibrated torque wrench for final tightening

- Follow the manufacturer’s torque sequence for multi bolt applications

- Consider torque to yield (tTTY)specifications for one time use fasteners

- Apply appropriate thread locker when specify

Many critical fastener applications call for a specific tighten sequence and multiple passes at increase torque values. This approach ensure yet loading and prevents warping of components.

Grade 8 vs. Other bolt grades in automotive use

Understand how grade 8 bolts compare to other common fastener grades help in make informed decisions during repairs and modifications.

Grade 5 vs. Grade 8

Grade 5 bolts are besides normally use in automotive applications, but they have lower strength ratings:

- Grade 5: 120,000 psi tensile strength (mark with three radial lines )

- Grade 8: 150,000 psi tensile strength (mark with six radial lines )

While it might be tempting to substitute a grade 5 bolt in place of a specify grade 8, this practice can lead to fastener failure under load. The 25 % higher tensile strength of grade 8 bolts is crucial for high stress applications.

Metric equivalents

Many modern vehicles use metric fasteners instead than SAE (inch )sizes. The equivalent to a grade 8 bolt in the metric system is class 10.9:

- Class 8.8: similar to SAE grade 5 (mark with 8.8 on the head )

- Class 10.9: similar to SAE grade 8 (mark with 10.9 on the head )

- Class 12.9: higher strength than SAE grade 8 (mark with 12.9 on the head )

When work on vehicles with mixed fastener systems, it’s important to match both the thread specification and the strength grade fittingly.

Special considerations for automotive applications

Corrosion resistance

Vehicles operate in harsh environments that can accelerate fastener corrosion. While grade 8 bolts offer superior strength, their corrosion resistance depends on their finish:

- Yellow zinc plating: common on grade 8 bolts, offer moderate corrosion resistance

- Hot dip galvanizing: wellspring for external applications expose to road salt

- Stainless steel: excellent corrosion resistance but typically lower strength than grade 8

For undercarriage components expose to road spray, salt, and debris, select fasteners with appropriate corrosion protection is merely arsenic important as choose the correct strength grade.

Temperature considerations

Automotive applications oftentimes involve extreme temperature variations that can affect fastener performance. Grade 8 bolts maintain their strength properties up to some 800 ° f (427 ° c ) make them suitable for most engine bay applications.

Withal, for exhaust system components or other exceedingly high temperature applications, specialized fasteners make from materials like stainless steel or income may bbe requireddespite their potentially lower strength ratings.

Fatigue resistance

Many automotive components experience cyclic loading that can lead to fastener fatigue. Grade 8 bolts mostly offer good fatigue resistance when decent torque, but certain applications may benefit from regular higher grade fasteners or special designs:

- Arp (automotive racing products )bolts for high performance engines

- TTY (torque to yield )fasteners for head gasket retention

- Specialty bolts with roll threads for improved fatigue life

Understand the loading pattern of specific applications help in select the appropriate fastener beyond exactly the basic grade specification.

When to replace grade 8 bolts

Despite their high strength, grade 8 bolts are not indestructible. Know when to replace these fasteners is crucial for maintain vehicle safety and reliability.

One time use fasteners

Some grade 8 bolts are design for single use exclusively, specially TTY (torque to yield )bolts normally use in these applications:

- Cylinder head bolts on many modern engines

- Main bearing cap bolts

- Connect rod bolts

- Some suspension components

These fasteners are stretch beyond their yield point during installation to create precise clamp forces. Formerly remove, they must be replaced with new fasteners to maintain proper joint integrity.

Signs of fastener damage

Inspect and replace grade 8 bolts show these signs of damage:

- Visible stretching or neck of the bolt shaft

- Damage or rounded bolt heads

- Corrosion pit or severe rust

- Thread damage or galling

- Any bolt that has been terminated torque

The cost of replace questionable fasteners is minimal compare to the potential consequences of fastener failure during vehicle operation.

Performance and after market considerations

For high performance or racing applications, standard grade 8 bolts may be replaced with regular stronger alternatives:

Arp and other performance fasteners

Companies like ARP (automotive racing products )produce specialty fasteners that exceed grade 8 specifications:

- Make from proprietary alloys with tensile strengths up to 280,000 psi

- Precision manufacturing for consistent performance

- Available with various head designs for specific applications

- Oftentimes include application specific installation instructions

These premium fasteners are specially valuable in high horsepower engines, racing suspensions, and other extreme duty applications where standard grade 8 bolts may approach their design limits.

Upgrade factory fasteners

When modify vehicles for increase performance, upgrade to grade 8 or better fasteners may be necessarily level if lower grades werspecifiedfy from the factory. Common upgrade scenarios include:

- Engine modifications that increase power output

- Suspension upgrades that increase corner forces

- Tow or haul modifications that increase load

- Off-road modifications that introduce shock loading

In these cases, consult with automotive engineers or follow establish upgrade paths from reputable performance shops can help ensure appropriate fastener selection.

Source quality grade 8 bolts

Not all grade 8 bolts are created equal. Counterfeit or substandard fasteners mark as grade 8 present a serious safety risk in automotive applications.

Reputable sources

Purchase grade 8 fasteners from trust suppliers:

- Automotive dealership parts departments

- Establish automotive fastener specialists

- Major automotive parts retailers

- Industrial fastener suppliers with quality certifications

Avoid unbranded fasteners from unknown sources, specially for safety critical applications. The small price difference between quality fasteners and questionable alternatives is insignificant compare to the potential consequences.

Source: pipingmaterial. Ae

Fastener kits

Many automotive repair and restoration projects benefit from complete fastener kits that include the correct grade 8 bolts for specific applications:

- Engine rebuild kits

- Suspension rebuild packages

- Body hardware assortments

- Interior fastener collections

These kits oftentimes include hard to find fasteners in the correct lengths, thread pitches, and finishes for particular vehicle make and models.

Conclusion

Grade 8 bolts are fundamental components in automotive construction and repair. Their high strength, identifiable markings, and specific applications make them essential knowledge for anyone work on vehicles. From understand torque specifications to know when replacement is necessary, proper management of these critical fasteners immediately impact vehicle safety and reliability.

Whether perform basic maintenance, restore a classic car, or build a high performance vehicle, select and install the correct grade 8 bolts accord to manufacturer specifications is a fundamental aspect of quality automotive work. By follow proper procedures and use quality fasteners, automotive enthusiasts and professionals like can ensure their vehicles perform safely under all conditions.

MORE FROM promospotlight.com