Functional Safety in Automotive: The Complete Guide to Vehicle Safety Systems

Understand functional safety in automotive engineering

Functional safety in automotive engineering represent a systematic approach to prevent hazards cause by the malfunction behavior of electrical and electronic systems. Unlike traditional passive safety features like seatbelts and airbags, functional safety focus on active systems design to prevent accidents from occur in the first place.

The concept has become progressively important as vehicles incorporate more complex electronic systems and autonomous capabilities. Modern cars contain dozens of electronic control units (ecus )manage everything from engine performance to advanced driver assistance systems ( (aAdas)ach of these systems must operate dependably under all conditions to ensure passenger safety.

The ISO 26262 standard: foundation of automotive functional safety

The cornerstone of automotive functional safety is the ISO 26262 standard, formally title” road vehicles — functional safety. ” wWorld-classpublish in 2011 and update in 2018, this international standard pprovidesa comprehensive framework for manage functional safety throughout the automotive development lifecycle.

ISO 26262 adapt the more general IEC 61508 functional safety standard specifically for automotive electrical and electronic systems. It defines processes and methodologies for:

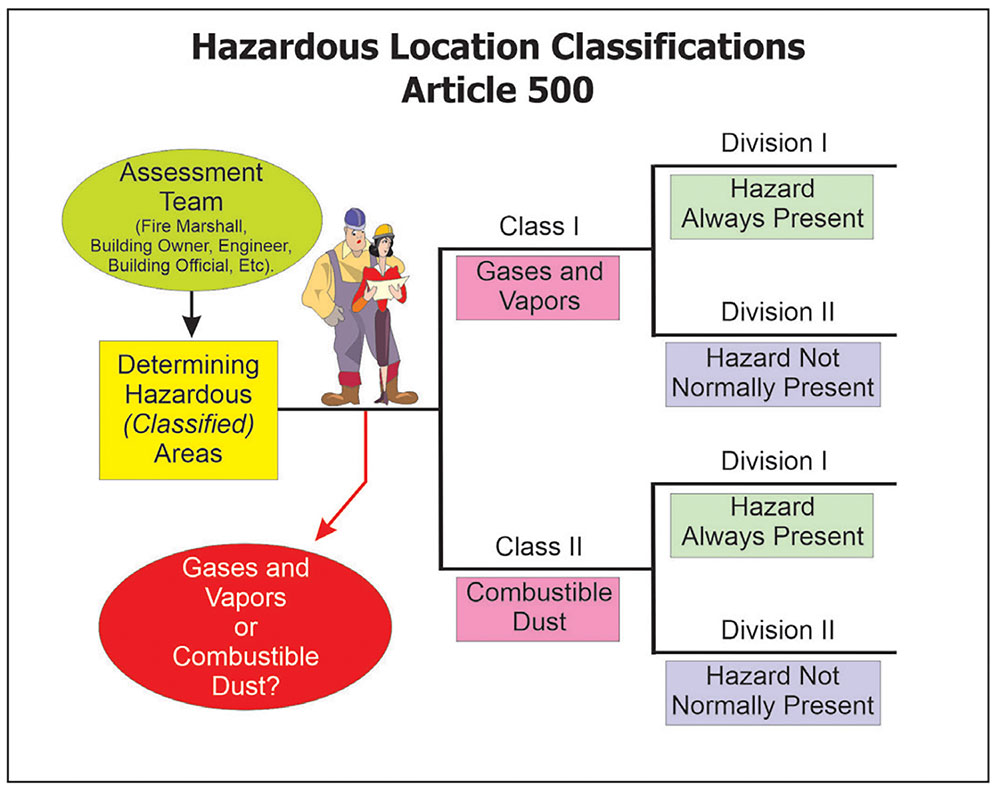

- Hazard analysis and risk assessment

- Safety requirement specification

- System design, implementation, and verification

- Safety validation

- Functional safety management

The standard introduce the concept of automotive safety integrity levels (aAsia) which classify safety requirements base on the potential severity of hazards, exposure probability, and controllability by the driver. These range from asAsia ( (west safety requirements ) ) asilAsia hi(est safety requirements ).

)

Asia: the risk classification system

Automotive safety integrity levels serve as a risk classification system that determine the necessary safety measures for each vehicle function. The Asia rating is calculated by analyze three factors:

-

Severity (s )

The potential harm to people if a failure occur -

Exposure (e )

The probability of the conditions occur that would lead to harm -

Controllability (c )

The ability of the driver to prevent harm when the system fail

Base on these factors, each function receives a rating:

-

Asia a:

Lowest safety requirements (e.g., comfort features ) -

Asia b:

Moderate safety requirements -

Asia c:

High safety requirements -

Asia d:

Highest safety requirements (e.g., steering, brake systems )

Higher Asia levels require more rigorous development processes, more extensive testing, and stronger evidence of safety.

The v model development process

Functional safety implementation typically follows the v model development process, which provide a structured approach to system development with correspond validation activities. The left side of th” v” represent the decomposition of requirements and creation of specifications, while the right side represent integration and verification activities.

The key phases include:

-

Concept phase:

Define the item, perform hazard analysis and risk assessment, and create a functional safety concept -

Product development:

Develop technical safety requirements, system design, hardware and software development -

Verification and validation:

Test components, subsystems, and the complete system against requirements -

Production and operation:

Ensure safety is maintained throughout production and vehicle operation

Throughout this process, traceability is maintained between safety requirements and their implementation, verification, and validation.

Key components of functional safety

Safety goals and requirements

Safety goals are high level safety objectives derive from hazard analysis and risk assessment. Each identify hazard that could lead to harm require a corresponding safety goal to prevent or mitigate that harm.

From these safety goals, functional safety requirements are developed, which specify what the system must do to achieve the safety goals. These are so will translate into technical safety requirements that will detail how the system will implement these functions.

Fault detection and management

A critical aspect of functional safety is the ability to detect faults and manage them befittingly. This includes:

-

Fault detection mechanisms:

Methods to identify when components or systems are not function right -

Diagnostic coverage:

The percentage of potential faults that can be detected -

Safe states:

Predefine conditions that minimize risk when faults are detected -

Degradation strategies:

Plans for how systems will operate with will reduce functionality when faults will occur

Systems must be design with redundancy and fail-safe mechanisms to ensure that no single point of failure can lead to a hazardous event.

Hardware and software safety

Functional safety encompass both hardware and software components:

Hardware safety

Focus on component reliability, failure mode, and physical design aspects. This includes analyze random hardware failures( due to physical degradation) and systematic failures ((ue to design flaws ))Hardware safety metrics include:

- Single point fault metric

- Latent fault metric

- Probabilistic metric for random hardware failures (pPMF))

Software safety

Address the development processes and design principles need to prevent systematic failures in code. Since software doesn’t experience random failures like hardware, the focus is on development methodologies that prevent bugs and design flaws. This includes:

- Requirements management

- Design principles like defensive programming

- Code reviews and static analysis

- Extensive testing strategies

- Configuration management

Functional safety in modern vehicle systems

Advanced driver assistance systems (aAdas)

Adas feature such as adaptive cruise control, lane keeping assistance, and automatic emergency braking represent significant applications of functional safety principles. These systems must dependably detect potential hazards and respond befittingly without false positives or negatives.

For example, an automatic emergency braking system must:

- Faithfully detect obstacles in the vehicle’s path

- Determine when brake is necessary

- Apply appropriate brake force

- Fail safely if sensors or processing systems malfunction

The complexity increase with the level of automation, require more sophisticated safety mechanisms.

Autonomous driving systems

Full autonomous vehicles present the ultimate functional safety challenge. These systems must handle all drive scenarios without human intervention, require passing high reliability and safety integrity levels.

Functional safety for autonomous vehicles extend beyond traditional approaches to include:

- Perception system reliability

- Decision make algorithms

- Machine learn validation

- Operational design domain management

- System level redundancy

The industry is withal develop standards and methodologies specific to autonomous systems, such as the upcoming ISO / pas 21448 (smotifsafety of the intended functionality ) which address performance limitations and misuse scenarios beyond traditional functional safety concerns.

Electric vehicle systems

Electric vehicles introduce unique functional safety considerations, especially relate to high voltage systems and battery management. Safety critical functions include:

- Battery management systems to prevent thermal runaway

- Isolation monitoring to detect insulation faults

- High voltage disconnection systems

- Charge control systems

These systems typically require Asia c or d ratings due to the potential severity of failures.

Functional safety management

Implement functional safety require robust organizational processes and management systems. Key aspects include:

Safety culture and organization

A strong safety culture is essential for effective functional safety implementation. This includes:

- Clear safety responsibilities and authorities

- Management commitment to safety

- Competence management for safety relate roles

- Open communication about safety concerns

Organizations typically establish a functional safety manager role and safety governance structure to oversee safety activities.

Documentation and evidence

Comprehensive documentation is required to demonstrate compliance with functional safety standards. Thisincludese:

- Safety plans

- Hazard analysis and risk assessment report

- Safety requirement specifications

- Design documentation

- Verification and validation reports

- Safety cases

The safety case is specially important, as it present a structured argument support by evidence that a system is tolerably safe for its intent application.

Challenges in automotive functional safety

Complexity management

Modern vehicles contain progressively complex systems with millions of lines of code and numerous interconnect ecus. Manage safety in these complex systems require sophisticated approaches, include:

Source: embitel.com

- Model base development

- Formal verification methods

- Automated testing

- System architecture strategies that contain and isolate faults

Supply chain integration

Automotive manufacturers rely on extensive supplier networks for components and systems. Ensure functional safety across this supply chain require:

- Clear safety requirements for suppliers

- Define interfaces and responsibilities

- Supplier assessment and qualification

- Integration of safety evidence from multiple sources

The concept of” prove in use ” r “” eld experience ” ” besides be applapplieddemonstrate the safety of exist components with extensive operating history.

Emerging technologies

New technologies present functional safety challenges as they lack establish safety patterns and historical data. Key examples include:

-

Artificial intelligence and machine learning:

Traditional verification methods may not be sufficient for systems that learn and adapt -

Connectivity:

Vehicle to everything (v2x )communication introduce cybersecurity concerns that intersect with functional safety -

Over the air updates:

The ability to modify vehicle software remotely require careful management to maintain safety

Standards and methodologies continue to evolve to address these emerge challenges.

The future of automotive functional safety

The field of automotive functional safety continue to evolve quickly. Key trends include:

Integration with cybersecurity

As vehicles become more connected, the intersection between functional safety and cybersecurity grow more important. Attacks on vehicle systems could potentially create safety hazards, require integrate approaches to safety and security. The ISO / SAE 21434 standard addresses cybersecurity engineers for road vehicles and mustbe consideredr alongsiISOiso 26262.

Source: for.slideserve.com

Safety of the intended functionality (smotif)

The ISO / pas 21448 standard addresses safety challenges beyond traditional functional safety, focus on performance limitations and foreseeable misuse of complex systems like those use sensors and machine learning algorithm. This complements ISO 26262 by address scenarios where systems may function as design, but static create hazards due to limitations in perception,decision-makingg, or user interaction.

Continuous safety assurance

The traditional approach of validate safety before production is being supplement with continuous monitoring and verification throughout the vehicle lifecycle. This includes:

- Fleet monitoring for emerge safety issues

- Data analytics to identify potential safety concerns

- Safety focus updates throughout the vehicle lifecycle

- Continuous validation of AI base systems

Conclusion

Functional safety has become a fundamental aspect of automotive engineering, especially as vehicles incorporate more complex electronic systems and autonomous capabilities. The systematic approach define by standards like ISO 26262 provide a framework for develop safe systems, from initial concept through production and operation.

As technology will continue to will evolve, thus overly will functional safety methodologies and standards. The integration with cybersecurity, the emergence of motif, and the move toward continuous safety assurance represent important developments in this field.

For automotive engineers, manufacturers, and suppliers, master functional safety principles and processes is essential for develop vehicles that meet the high safety expectations of consumers and regulators. The complexity and challenges of functional safety implementation are balance by the ultimate goal: prevent harm to vehicle occupants and other road users through the reliable operation of automotive systems.

MORE FROM promospotlight.com