Driving Innovation: The Future of Modular Vehicle Platforms

Photo by Theodor Vasile on Unsplash

Introduction

The automotive industry is undergoing a paradigm shift, with modular vehicle platforms at the heart of future innovation. These platforms promise unprecedented flexibility, cost efficiency, and sustainability, allowing manufacturers to quickly respond to market demands and technological advancements. As electrification, autonomy, and consumer customization accelerate, understanding the future trajectory of modular platforms is essential for industry leaders, fleet operators, and even urban planners.

What Are Modular Vehicle Platforms?

Modular vehicle platforms are standardized, highly adaptable chassis and component systems that support a wide range of vehicle types-from compact cars to commercial vans-using shared core elements like battery modules, electric motors, and digital architectures. This approach enables manufacturers to produce multiple models with significant parts commonality, reducing costs and complexity while increasing scalability and speed to market [4] .

Key Trends Shaping the Future

Software-Defined Vehicles & Over-the-Air Updates

One of the most transformative trends is the shift toward software-defined vehicles . Modular platforms now integrate robust digital systems, allowing manufacturers to deploy over-the-air (OTA) updates that continuously improve vehicle performance, safety features, and user experience without physical intervention. This reduces reliance on traditional hardware upgrades and accelerates innovation cycles [1] .

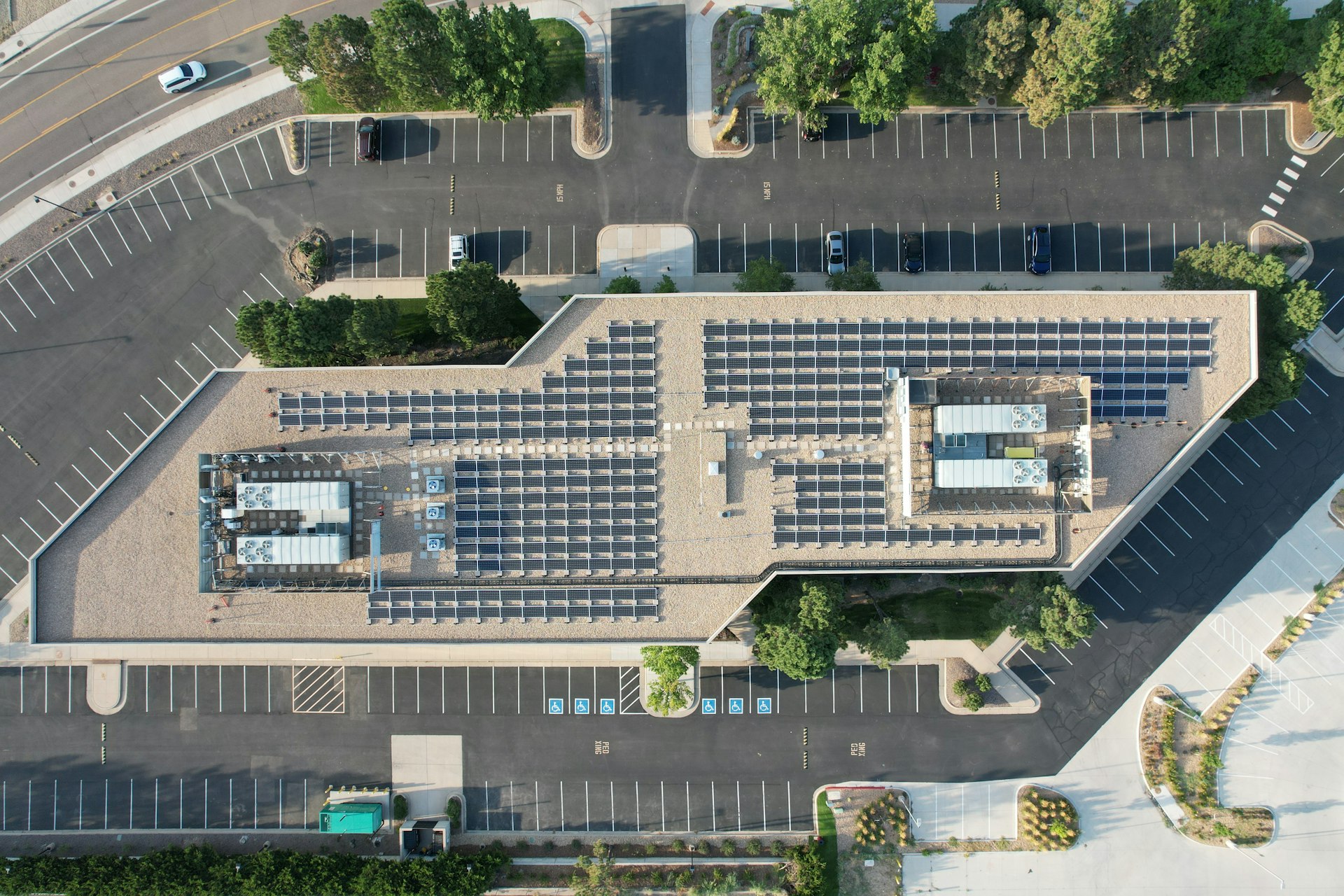

Sustainability & Renewable Integration

Environmental responsibility is central to next-generation modular platforms. Manufacturers are increasingly using sustainable materials , optimizing battery recycling, and integrating renewable energy sources into their production processes. This commitment to sustainability not only aligns with regulatory pressures but also with consumer demand for eco-friendly mobility solutions [1] .

Battery-as-a-Service (BaaS)

The rise of Battery-as-a-Service models is reshaping the ownership experience. Rather than purchasing batteries outright, consumers and fleet operators may soon opt for subscription-based battery services, lowering upfront costs and providing flexibility for upgrades and replacements. This can make electric vehicles (EVs) more accessible, though availability and terms may vary by region and provider [1] .

High-Performance Computing & AI Integration

Automotive manufacturers are leveraging high-performance computing for vehicle design and autonomous system development. Advanced AI algorithms facilitate the integration of Level 2 and Level 3 autonomous features, improving safety and responsiveness. These technologies require modular platforms capable of supporting rapid upgrades and new functionalities [1] .

Real-World Applications and Case Studies

Volkswagen Group’s MEB Platform

The Volkswagen Group’s Modular Electric Drive Matrix (MEB) platform exemplifies modular flexibility. Supporting compact to large vehicles, MEB enables scalable battery options and multiple drive configurations, serving brands such as Volkswagen, Audi, Skoda, and SEAT. By 2025, over a million EVs are expected to use this platform, driving the transition to mainstream electric mobility [2] .

Photo by TSD Studio on Unsplash

Hyundai’s Integrated Modular Architecture (IMA)

Hyundai is launching its Integrated Modular Architecture (IMA), which supports two platforms: EM for passenger EVs and ES for commercial and purpose-built vehicles. Both use a common core of scalable components, enabling rapid development across diverse vehicle types-from luxury SUVs to robotaxis and cargo vans. This approach is expected to reduce costs, streamline development, and support a wider range of electric vehicles [3] .

Mercedes-Benz & Flexis: Modular Commercial Vehicles

Mercedes-Benz’s Van Electric Architecture (VAN.EA) and Van Combustion Architecture (VAN.CA) share up to 70% common parts, supporting both electric and combustion-engine vans on the same production line. Similarly, the Renault-Volvo Flexis joint venture leverages a modular electric platform for multiple models, enhancing efficiency and cost-competitiveness in the commercial sector [4] .

Actionable Steps for Industry Adaptation

1. Assess Platform Requirements

Organizations should begin by identifying their specific vehicle needs-whether for passenger cars, commercial fleets, or specialized transport. This includes evaluating anticipated capacity, range, charging infrastructure, and regulatory requirements. Automotive consultants and platform providers may offer tailored assessments to guide platform selection.

2. Engage with OEMs and Platform Developers

Collaboration with established original equipment manufacturers (OEMs) and modular platform specialists is critical. Companies like Volkswagen, Hyundai, and Mercedes-Benz have dedicated industry outreach and partnership teams. To explore opportunities, you can contact OEM business development departments or attend industry events such as the EV Platform Summit or Automotive IQ conferences.

3. Explore Financial Incentives

Many governments and industry groups are offering financial incentives for sustainable transportation and modular platform adoption. To discover relevant programs, search for ‘EV manufacturing incentives’, ‘modular platform grants’, or consult official agencies such as the U.S. Department of Energy or European Commission. You may also contact local chambers of commerce for regional support opportunities [5] .

4. Evaluate Battery and Charging Solutions

Modular platforms increasingly support standardized battery packs and fast-charging interfaces. When considering platform adoption, review available battery-as-a-service models and charging network compatibility. Reach out to EV infrastructure providers for up-to-date offerings, and investigate partnerships with battery leasing companies for flexible, scalable energy solutions [1] .

5. Plan for Customization and Upgrades

The modular approach enables tailored vehicle configurations and easy component upgrades. Engage with platform suppliers to discuss options for future-proofing your fleet or product line, including the ability to swap or enhance software, batteries, or drive systems as technology evolves. Consider pilot programs to test modular upgrades in real-world scenarios before full-scale adoption.

Challenges and Solutions

Despite clear benefits, modular platforms present challenges such as initial investment costs, the need for workforce retraining, and ensuring interoperability across different models and suppliers. These can be addressed by:

- Pursuing industry partnerships to share development risks and costs

- Investing in employee education and technical training programs

- Participating in industry standardization bodies to promote interoperability

- Running phased implementation pilots before committing to large-scale rollouts

For assistance, connect with automotive industry associations and technical consultancies specializing in modular system integration.

Alternative Approaches and Future Directions

Some manufacturers are experimenting with hybrid architectures that integrate modular systems with traditional manufacturing methods. This allows legacy vehicles to coexist with new modular designs, providing flexibility during the transition period. Urban planners and construction firms are also adopting modular transportation systems to address congestion and sustainability goals in rapidly growing cities [5] .

How to Access Opportunities in Modular Vehicle Platforms

To actively participate in the modular vehicle platform revolution, consider the following steps:

- Research leading OEMs and platform providers through reputable automotive industry portals and official manufacturer websites.

- Attend industry events, webinars, and trade shows focused on EV platforms and manufacturing innovation.

- Consult with government agencies like the U.S. Department of Energy or European automotive authorities for guidance on incentives and regulatory compliance.

- Network with suppliers and partners offering battery-as-a-service, charging infrastructure, and modular upgrade solutions.

- Review case studies and technical whitepapers from established sources such as Automotive IQ, Market Report Analytics, and Stream Modular for actionable insights.

If direct links to programs or services cannot be verified, use official agency search functions and industry directories for authoritative information. For technical consultation, use search terms like “modular EV platform integration consulting” or contact automotive business development teams via official channels.

Conclusion

The future of modular vehicle platforms is defined by flexibility, sustainability, and rapid innovation. As the market matures, industry stakeholders who embrace modular design and strategic adaptation will be best positioned to capitalize on evolving transportation demands. The journey involves careful planning, collaboration with trusted partners, and ongoing engagement with emerging technologies and regulatory trends.

References

- [1] Market Report Analytics (2025). Modular EV Platforms Market Expansion: Growth Outlook 2025-2033.

- [2] Automotive IQ (2025). Top 5 EV Platforms Transforming the Automotive Industry.

- [3] TS2.tech (2025). Global EV Powertrain and Platform Developments (May-June 2025).

- [4] Automotive Manufacturing Solutions (2025). Modular manufacturing moves automotive production into the future.

- [5] Stream Modular (2025). The Future of Efficient Modular Transportation: Trends to Watch in 2025.

MORE FROM promospotlight.com