Driving Change: How Sustainable Materials Are Shaping the Future of Automotive Manufacturing

Photo by Lenny Kuhne on Unsplash

Introduction: The Urgency of Sustainable Materials in Automotive Manufacturing

The automotive industry is undergoing a profound transformation as environmental concerns, regulatory pressures, and consumer demand for greener products accelerate the shift towards sustainability. Central to this evolution is the adoption of sustainable materials -eco-friendly alternatives that reduce the sector’s carbon footprint and foster responsible resource use. For automotive manufacturers and suppliers, understanding and implementing sustainable materials is no longer optional; it is a strategic imperative that supports competitiveness, regulatory compliance, and long-term profitability [1] .

What Are Sustainable Automotive Materials?

Sustainable automotive materials refer to substances sourced from renewable, recycled, or responsibly managed resources. These materials are engineered to minimize environmental impact, not only during production but across their entire lifecycle-including use, recycling, and disposal. They include recycled plastics, bio-based composites, innovative fibers, and more. The goal is to reduce waste, emissions, and energy consumption while maintaining or improving vehicle performance [1] .

Key Types of Sustainable Materials in Automotive Manufacturing

1. Recycled Plastics

Automakers are increasingly using plastics derived from post-consumer waste, such as recycled water bottles, in a variety of vehicle components. For example, Ford has integrated recycled plastic bottles into underbody shields, significantly reducing landfill waste and the overall carbon footprint. According to industry data, plastics now comprise less than 10% of a typical vehicle’s weight but account for about 50% of its volume, supporting weight reduction and improved fuel efficiency [2] .

2. Natural Fiber Composites

Materials like hemp, flax, kenaf, agave, bamboo, and seaweed are being developed as sustainable alternatives to traditional composites. These renewable fibers are used in interior components such as door panels, dashboards, and seatbacks, offering both strength and significant weight reduction. For instance, biocomposites like NAFILean-R combine hemp fibers with recycled polypropylene, resulting in a 20% lighter material and up to 90% lower cradle-to-gate COâ‚‚ emissions compared to conventional plastics. The Renault 5 E-Tech features such materials, demonstrating their real-world feasibility [3] [5] .

3. Bio-Based and Recycled Foams

Bio-based foams derived from plant oils and recycled content are replacing traditional petroleum-based foams in seats and insulation. This switch reduces dependence on fossil fuels and minimizes chemical use, while still offering comfort and durability. Manufacturers are also exploring the use of agave and bamboo-based foams and trim coverings, especially in luxury and electric vehicles, further reducing water and chemical consumption [5] .

4. Lightweight Metals and Hybrid Materials

Although safety requirements make exterior applications more challenging, manufacturers are investigating the use of aluminum, advanced steels, carbon fiber, and hybrid materials. One innovation, the Nano Cellulose Vehicle developed in Japan, utilizes cellulose fiber from agricultural waste, resulting in a body that is one-fifth the weight of steel while being five times as strong. Similarly, natural-fiber-reinforced plastics have achieved up to 60% weight reduction in car body panels, as seen in the Fraunhofer Institute’s Bio-Concept Car [4] .

5. Sustainable Tire Materials

Tire manufacturers face increasing pressure to use renewable and responsibly sourced materials. Continental, in partnership with research institutes, has developed tires using natural rubber from Russian dandelion plants. These tires perform comparably to traditional models and are poised for large-scale production, with the added benefit of a faster and more sustainable rubber supply chain [4] .

Benefits of Adopting Sustainable Materials

Integrating sustainable materials in automotive manufacturing offers multiple, measurable advantages:

- Reduced Environmental Footprint : Lower lifecycle COâ‚‚ emissions, less landfill waste, and decreased use of non-renewable resources.

- Improved Fuel Efficiency : Lighter materials contribute to lower vehicle weight, which directly improves fuel or energy efficiency for both internal combustion and electric vehicles.

- Regulatory Compliance : Many jurisdictions are tightening environmental and recycling regulations; sustainable materials help manufacturers stay ahead of evolving standards.

- Market Differentiation : As consumers become more eco-conscious, vehicles with sustainable interiors and components can command premium pricing and brand loyalty.

- Supply Chain Resilience : Diversifying material sources, especially with bio-based and recycled inputs, can reduce dependence on volatile raw material markets.

Implementation: Step-by-Step Guidance for Integrating Sustainable Materials

If you are an automotive manufacturer, supplier, or materials engineer seeking to implement sustainable materials, consider these practical steps:

- Assess Current Material Use : Conduct a full lifecycle assessment (LCA) of existing materials, focusing on areas with the highest environmental impact and cost.

- Identify Alternative Materials : Research suppliers offering recycled plastics, natural fibers, or bio-based foams that meet your technical and regulatory requirements. Industry events, such as the CARES Sustainable Forum, regularly showcase the latest advancements and supplier networks [1] .

- Prototype and Test : Develop prototypes using target sustainable materials. Subject these to rigorous testing to ensure safety, performance, and durability meet or exceed conventional standards.

- Collaborate with Partners : Engage with innovative startups, R&D centers, and established material suppliers. For example, MATERI’ACT, part of FORVIA, partners with organizations such as Veolia and Plastic Odyssey to develop new biocomposites and recycled materials [3] .

- Scale Production : Once validated, scale up the use of sustainable materials across more vehicle models and components, tracking performance and sustainability metrics closely.

- Market and Communicate : Highlight your sustainability initiatives in customer communications, marketing, and regulatory reporting. Transparency about material sourcing and lifecycle benefits helps build consumer trust and brand value.

If you are seeking suppliers or technical partners, consider searching for “automotive sustainable material suppliers,” “bio-based automotive composites,” or “recycled plastic car parts.” Many industry associations and technology forums maintain directories of certified suppliers and research partners.

Challenges and Solutions in Adopting Sustainable Materials

While the benefits are clear, several challenges remain:

- Cost and Scale : Sustainable materials can be more expensive or less available at scale. Manufacturers can mitigate this by forming industry partnerships, investing in R&D, and seeking government incentives where available.

- Technical Performance : Not all sustainable materials meet the stringent safety and durability standards required for automotive applications. Rigorous testing, phased adoption, and hybrid solutions (mixing sustainable and conventional materials) can bridge these gaps.

- Supply Chain Complexity : Sourcing consistent, high-quality sustainable materials globally can be complex. Building resilient, transparent supplier networks and leveraging digital tracking tools can help manage this complexity.

Real-World Examples and Case Studies

Several major automotive brands have made public commitments and demonstrated real-world progress:

- Ford uses recycled plastics in underbody shields, diverting millions of plastic bottles from landfills each year [2] .

- Volkswagen has pledged to use 100% recycled materials in all fabrics, carpets, and seats for its EV range by the late 2020s [2] .

- Renault 5 E-Tech incorporates biocomposites made from hemp and recycled polypropylene, achieving up to 90% reduction in material-related emissions [3] .

- Continental Tires is moving towards the use of dandelion-sourced natural rubber for tires, with comparable performance and much faster crop cycles [4] .

How to Access Sustainable Automotive Materials and Suppliers

While there is no single universal directory, you can:

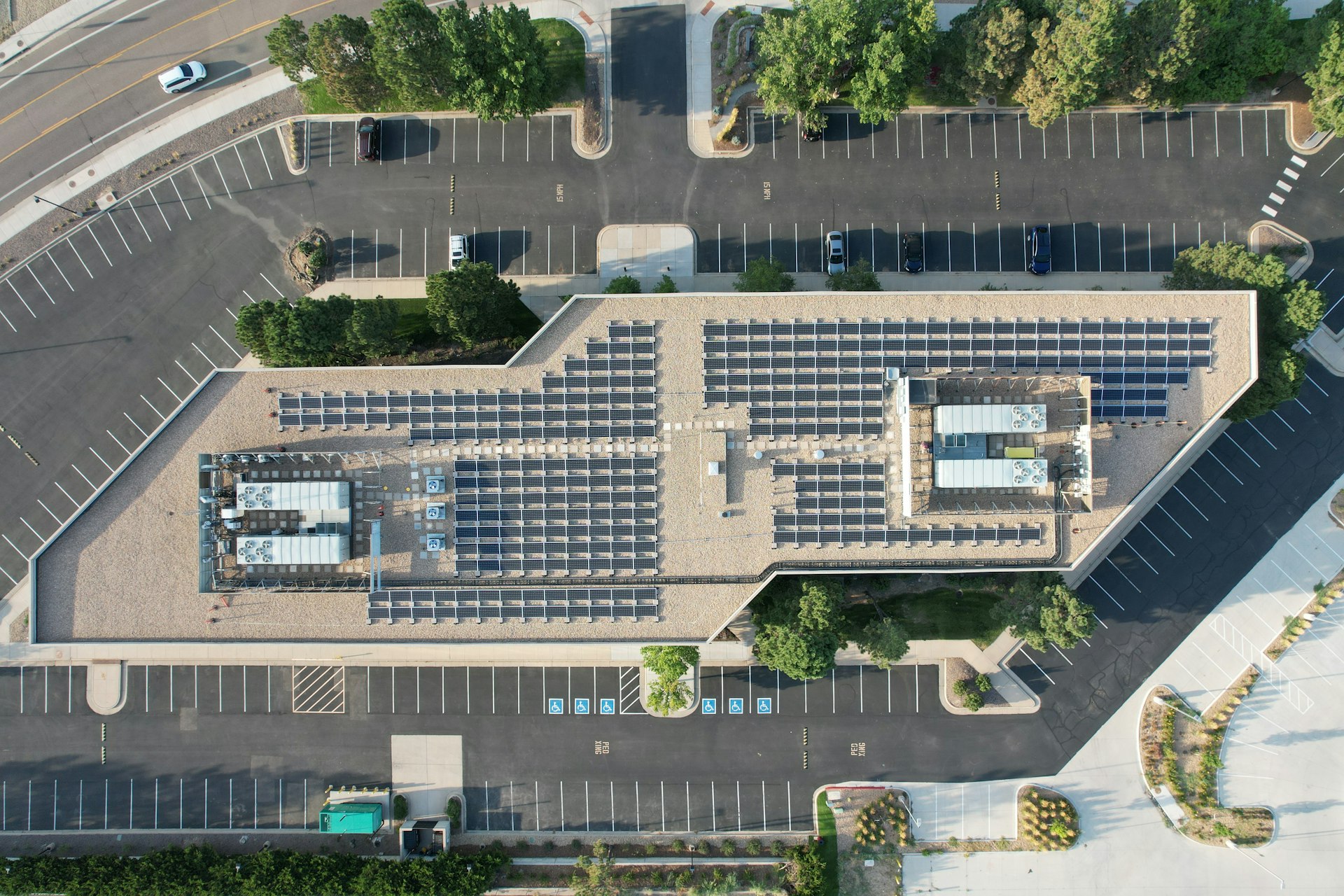

Photo by Amin Hasani on Unsplash

- Contact industry associations such as the Society of Automotive Engineers (SAE) or regional automotive supplier groups for vetted supplier lists.

- Attend trade shows and forums like the CARES Sustainable Forum , which showcase the latest innovations and connect manufacturers with material innovators [1] .

- Search for academic research centers and R&D partnerships, such as those at the Fraunhofer Institute, focused on automotive sustainability [4] .

- Leverage online business-to-business platforms by searching for certified “automotive sustainable material suppliers.”

If you are interested in supplier partnerships or product sourcing, start by searching official industry directories or contacting leading automotive manufacturers’ procurement departments.

Summary

The integration of sustainable materials in automotive manufacturing is rapidly moving from innovation to industry standard. By adopting recycled plastics, natural fibers, bio-based foams, and other advanced materials, manufacturers can significantly reduce environmental impact, improve efficiency, and build a resilient, forward-looking supply chain. With practical steps, real-world examples, and a network of industry partners, transitioning to sustainable materials is achievable for organizations of all sizes. For the latest developments, consider subscribing to reputable trade publications or industry newsletters.

References

- [1] CARES Sustainable Forum (2023). Sustainable automotive materials for a green car design.

- [2] Microban (2023). Top 5 trends in automotive materials.

- [3] FORVIA (2024). Waves of Innovation: Accelerating Sustainability in Automotive Materials.

- [4] Continental Tires (2023). Sustainable materials in cars of the future.

- [5] Assembly Magazine (2023). Automakers Opt for Sustainable Materials.

MORE FROM promospotlight.com