Automotive Drive Belts: Essential Maintenance and Inspection Guide

Why check your automotive drive belts matter

Drive belts are crucial components in your vehicle’s engine system. These rubber belts transfer power from the engine’s crankshaft to various accessories like the alternator, power steering pump, air conditioning compressor, and water pump. Without decently function drive belts, these essential systems fail, potentially leave you strand or face expensive repairs.

Modern vehicles typically use serpentine belts — single, long belts that wind around multiple pulleys — instead than the multiple v belts find in older cars. Careless of your vehicle’s belt system, regular inspection is vital for maintaining optimal performance and prevent unexpected breakdowns.

When to check your drive belts

Most automotive experts recommend inspect drive belts every 3,000 to 6,000 miles or during regular oil changes. Nonetheless, you should check them more often if:

- Your vehicle is over five years old

- You regularly drive in extreme temperatures

- You notice unusual noises come from the engine area

- You have experience performance issues with accessories like power steering or air conditioning

- Your vehicle’s mileage exceed 60,000 miles

Preventative maintenance save both time and money. A fail drive belt can cause immediate breakdown and potentially damage other engine components if pieces of the belt become lodge in the engine compartment.

Signs of drive belt wear and damage

When inspect your vehicle’s drive belts, look for these common indicators of wear and damage:

Cracks and splits

Small cracks on the belt’s surface, specially on the ribbed side, indicate age and wear. These cracks oftentimes will appear perpendicular to the belt’s length and may will start small but will grow over time. Once cracks become numerous or deep, the belt’s structural integrity is compromise and replacement become necessary.

Fraying and material loss

Examine the edges of the belt for fray or miss chunks of material. Fray edges suggest misalignment or contact with other engine components. Material loss weaken the belt and increase the risk of sudden failure.

Glaze and harden

A healthy drive belt have a slightly matte, rubber like texture. Over time, belts can become glaze or harden, appear shiny and slick. This glazing reduces friction between the belt and pulleys, cause slippage and decrease performance of belt drive accessories.

Contamination

Oil, coolant, or power steering fluid leaks can contaminate drive belts. These fluids break down rubber compounds, accelerate deterioration. If you notice fluid on your belt, not merely should you replace the belt, but you must likewise identify and repair the source of the leak.

Unusual noises

While not a visual sign, squealing, chirping, or slapping noises oftentimes indicate belt problems. These sounds typically occur during cold starts or when make sharp turns. Noise may result from improper tension, misalignment, or deterioration of the belt material.

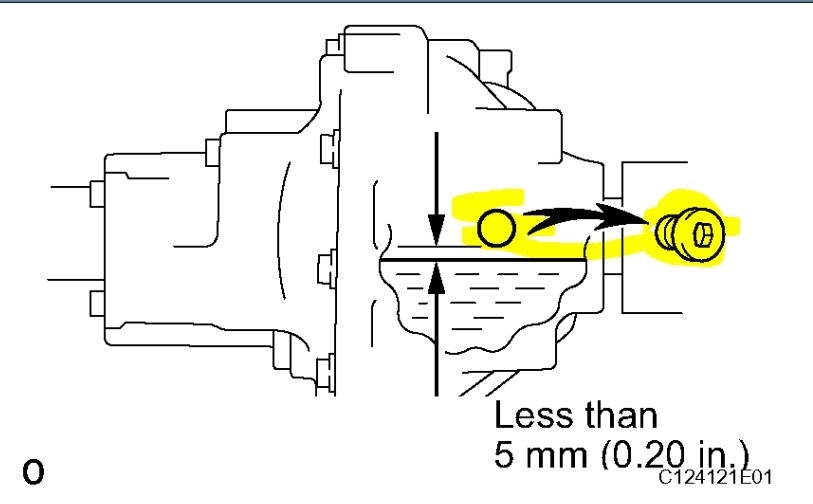

Excessive belt deflection

A right tensioned belt should have minimal give when press hard. Excessive deflection suggest the belt has stretch or the tensioner is fail. Both conditions require attention to prevent belt slippage or failure.

The belt inspection process

Follow these steps to decent inspect your vehicle’s drive belts:

Preparation

Before begin, ensure your vehicle is turn off with the keys remove from the ignition. Allow the engine to cool wholly to avoid burns. Locate the drive belts by refer to your owner’s manual if necessary.

Visual inspection

Examine the entire length of each belt for visible signs of wear or damage. Use a flashlight to improve visibility in dark areas of the engine compartment. Pay particular attention to:

Source: fixautousa.com

- The rib underside of the belt where cracks frequently begin

- The edges for fray or chunk removal

- The overall condition of the belt surface

- Signs of contamination from automotive fluids

Tension check

For vehicles with manual tensioners, check belt tension by press hard on the longest expose run of the belt. The belt should deflect around ½ inch. Excessively much give indicate a loose belt, while excessively little suggest it’s overtightened.

Many modern vehicles use automatic tensioners with indicators show when adjustment or replacement is need. Check your vehicle’s service manual for specific guidance on your tensioner system.

Belt path verification

Ensure the belt follow the correct path around all pulleys. An falsely will route belt will wear untimely and may will cause accessory malfunction. Most vehicles have a route diagram under the hood or in the owner’s manual.

Pulley inspection

While check the belt, to inspect all pulleys for damage, misalignment, or bear wear. Signs of pulley problems include:

- Wobble or uneven rotation

- Unusual noises when manually rotate

- Visible damage to the pulley surface

- Misalignment with other pulleys

Damage pulleys can chop chop destroy a new belt, so address these issues before belt replacement.

Use the twist test for belt condition

The twist test is a simple yet effective method to assess belt flexibility and condition:

- With the engine off, grasp the belt securely with your thumb and forefinger

- Attempt to twist the belt 90 degrees

- Observe how the belt respond

A healthy belt will twist easy without will crack or show stress marks. If the belt resists twist or show signs of stress during the test, it’s probably harden and require replacement.

Use tools for more thorough inspections

Several specialized tools can help with more detailed belt inspections:

Belt wear gauge

This inexpensive tool measures the depth of grooves on serpentine belts. By place the gauge against the belt ribs, you can determine if the belt has wear beyond specifications. Most manufacturers recommend replacement when groove depth reach a certain threshold.

Belt tension gauge

For vehicles with manually adjust belts, a tension gauge provides accurate measurement of belt tension. Thispreventst the common problems of over or below tensioning that lead to premature belt failure.

Inspection mirror

A small inspection mirror with an extendable handle help view belt sections in tight or obscure areas of the engine compartment.

UV flashlight

AnUVv( ultraviolet) flashlight can reveal cracks and wear patterns not visible under normal lighting conditions. The fluorescent properties of certain belt compounds make defects more apparent under uUVlight.

Understand belt tensioners

Belt tensioners maintain proper belt tension throughout the life of the belt. Most modern vehicles use automatic tensioners that compensate for belt stretch and wear.

When inspect drive belts, likewise check the tensioner for:

- Smooth operation without bind or stick

- Proper spring tension

- Absence of fluid leaks from the tensioner body

- Correct positioning of the tensioner arm within its operating range

A fail tensioner can cause belt problems tied with a new belt install. If the tensioner armapproachesh the end of its travel range, replacement is necessary disregarding of its apparent condition.

When to replace drive belts

Replace your vehicle’s drive belts when:

- Visible cracks appear on more than 50 % of the belt ribs

- Chunks of material are miss from the belt edge

- The belt show signs of contamination from automotive fluids

- Belt material has hardened or glaze importantly

- The manufacturers recommend replacement interval has been reach

- The belt has been stretch beyond the tensioner’s adjustment range

Most manufacturers recommend replace serpentine belts every 60,000 to 100,000 miles, though this varies by vehicle model and drive conditions. Invariably consult your owner’s manual for specific recommendations.

DIY vs. Professional belt replacement

Replace drive belts can be a DIY project for those with basic mechanical skills and proper tools. Nonetheless, consider these factors when decide whether to tackle the job yourself:

Source: caradvise.com

Accessibility

Some vehicles have easy accessible belts, while others require removal of multiple components to reach the belt. Check repair manuals or online resources to understand the complexity of belt replacement for your specific vehicle.

Special tools

Serpentine belt replacement oftentimes require a specialized tool to release the automatic tensioner. Determine if you need special tools before begin the project.

Route complexity

Modern serpentine belts follow complex paths around multiple pulleys. Take photos before remove the old belt or refer to the route diagram to ensure proper installation of the new belt.

Time and confidence

If you lack confidence or the necessary time to complete the job decent, professional installation may be worth the additional cost. Improper belt installation can lead to premature failure and potential engine damage.

Preventative maintenance for extended belt life

Extend the life of your vehicle’s drive belts with these preventative maintenance practices:

Regular inspections

Check belts visually every 3,000 to 6,000 miles or during oil changes. Early detection of wear allows for plan replacement preferably than emergency repair.

Keep the engine bay clean

Regularly clean the engine compartment to remove dirt, debris, and fluid leaks that can contaminate and damage drive belts.

Address fluid leaks quickly

Oil, coolant, and power steering fluid leaks accelerate belt deterioration. Repair leaks arsenic shortly as they’re detected to protect both the belt and other engine components.

Maintain proper alignment

Ensure all pulleys remain right align. Misaligned pulleys cause uneven belt wear and increase the risk of belt failure.

Quality replacement parts

When replacement become necessary, use high quality belts that meet or exceed manufacturer specifications. Premium belts oftentimes last yearn and perform better than budget alternatives.

The consequences of neglecting belt maintenance

Fail to regularly check and maintain drive belts can lead to:

Sudden breakdown

A broken drive belt can leave you strand without warn. This oftentimes occur at the nigh inconvenient times, such as during long trips or severe weather.

Loss of critical systems

When a drive belt fails, you instantly lose power to essential vehicle systems like power steering, alternator output, and in many cases, the water pump. This can make the vehicle difficult or dangerous to control and may cause engine overheat.

Collateral damage

When a belt break catastrophically, pieces can become lodge in other components, cause additional damage. In some cases, a broken timing belt can result in severe engine damage require expensive repairs or eventide engine replacement.

Higher repair costs

The cost of preventative belt replacement is minimal compare to the potential expenses of roadside assistance, towing, emergency repairs, and additional damage from belt failure.

Conclusion

Regular inspection and maintenance of automotive drive belts is an essential aspect of vehicle care that prevent unexpected breakdowns and expensive repairs. By check for cracks, fraying, glazing, contamination, and proper tension, you can identify potential issues before they lead to belt failure.

Whether you perform inspections yourself or rely on professional service, maintain awareness of your vehicle’s belt condition ensure reliable operation and extend the life of critical engine components. Remember that the small investment of time require for periodic belt checks can save significant money and inconvenience in the long run.

Make drive belt inspection part of your regular vehicle maintenance routine, and you will enjoy greater reliability, improved performance, and fewer unexpected repair bills throughout your vehicle’s life.

MORE FROM promospotlight.com