Automotive Battery Hazards: Classification and Gas Emissions

Understand automotive battery hazard classifications

Automotive batteries are essential components in vehicles, provide the necessary electrical power to start engines and operate various systems. Nonetheless, these power sources besides present specific hazards that require proper understanding and handling. Know the hazard classification of automotive batteries is crucial for safety during transportation, storage, and disposal.

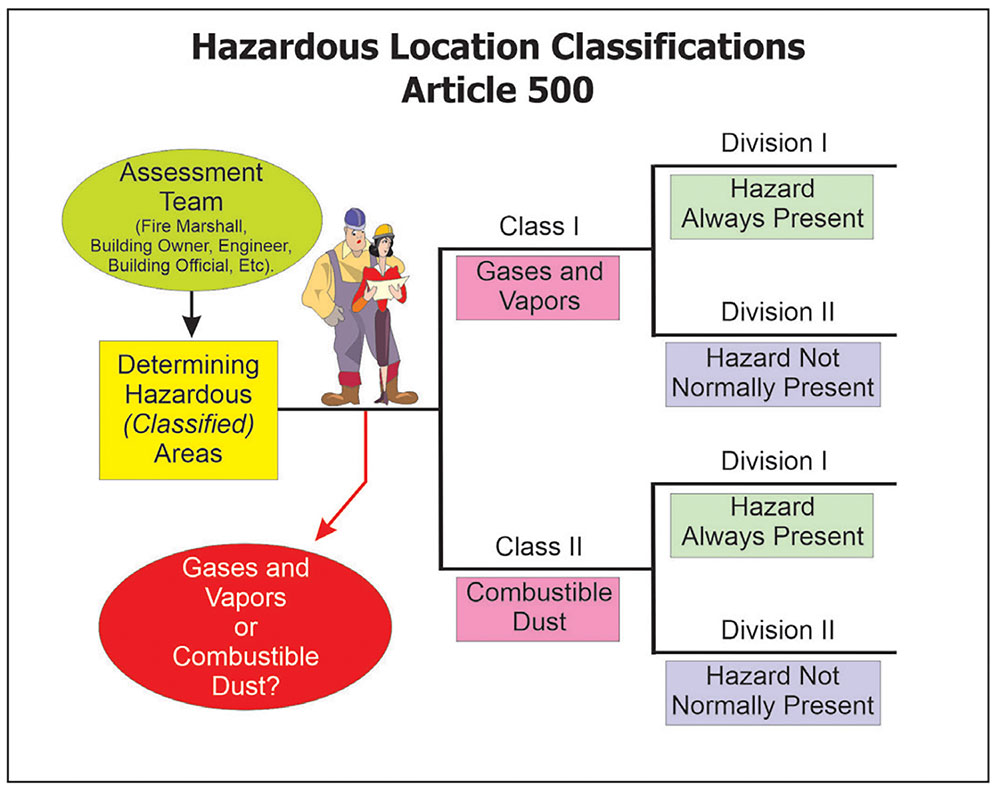

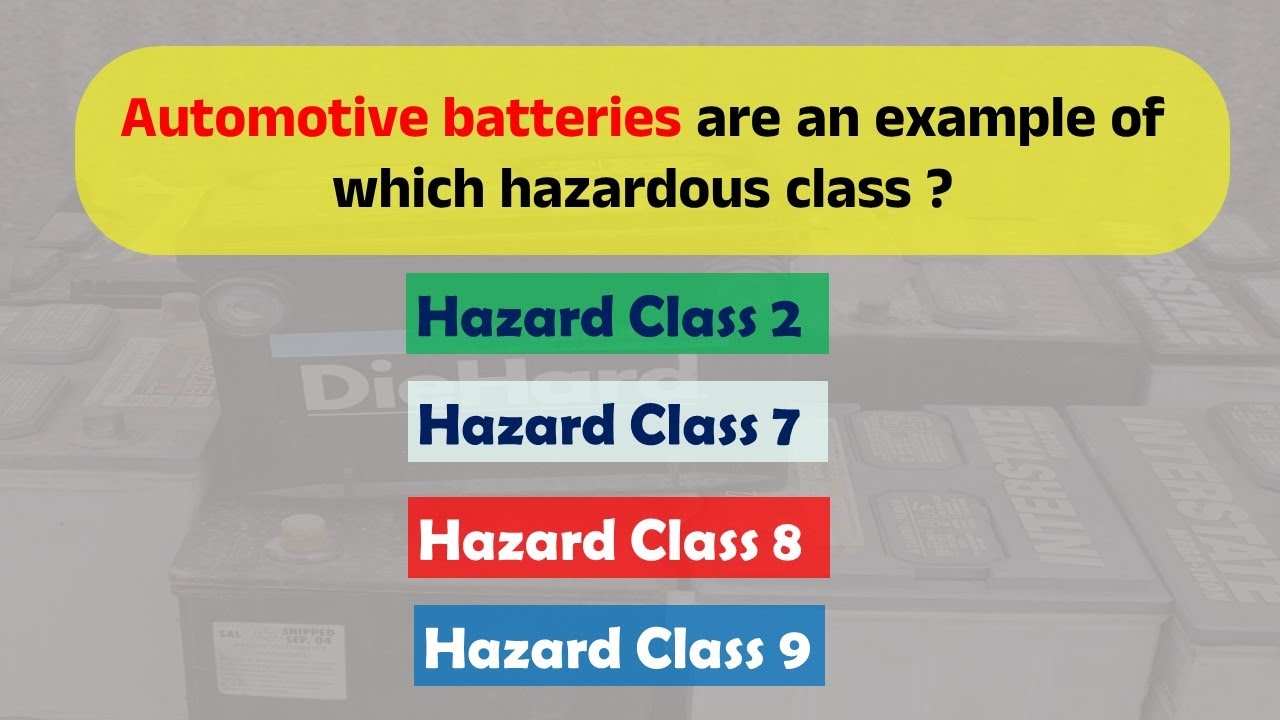

Hazard class of automotive batteries

Automotive batteries, especially the common 12 volt lead acid batteries find in most vehicles, are classified under

Hazard class 8 corrosive materials

. This classification is eestablishedby the department of transportation( dot) and the uUnited Nations globally harmonized system of classification and labeling of chemicals ((hGHS)

The class 8 designation indicate that these batteries contain substances that can cause severe damage to live tissue, corrode metals, or damage other materials through chemical action. This classification mainly stems from the sulfuric acid electrolyte contain within lead acid batteries, which have apHh of some 1.0, make it extremely corrosive.

Why automotive batteries are considered corrosive

The corrosive nature of automotive batteries come from several components:

- Sulfuric acid electrolyte solution (roughly 35 % concentration in typical lead acid batteries )

- Lead and lead compounds that can leach into the environment

- The potential for acid leakage during damage or improper handling

Contact with battery acid can cause chemical burns to skin and eyes, damage to clothing and equipment, and environmental contamination if improperly dispose of or allow leaking into soil or water systems.

Secondary hazard classifications

While the primary hazard classification for automotive batteries is class 8 (corrosive ) they may too present additional hazards:

Source: automotivean.com

Environmental hazard

Lead acid batteries contain toxic heavy metals (mainly lead )that pose significant environmental risks if not decent recycle or dispose of. The lead components and acid electrolyte can contaminate soil and water sources, make proper disposal essential.

Potential explosive hazard

Though not their primary classification, automotive batteries can present explosion risks under certain conditions due to the gases they produce. This aspect is frequently overlooked but is critically important for safe handling.

Explosive and accelerant gases release by lead acid batteries

One of the near significant, yet frequently underappreciated hazards of automotive lead acid batteries is their production of potentially explosive gases during normal operation, specially during charge cycles.

Hydrogen gas generation

The primary explosive gas release by automotive 12 volt lead acid batteries is

Hydrogen (hhe)

. Hydrogen is produce through a process call electrolysis, which occur course during battery charging. When a battery charges, water ((â‚‚HBO)n the electrolyte solution break down into hydrogen and oxygen gases.

Hydrogen gas present several significant hazards:

-

Extremely flammable

hydrogen have a real wide flammability range (( % to 75 % concentration in air )) -

Low ignition energy

it rrequiresrattling little energy to ignite (angstrom little as 0.02 mMJ) -

Invisible and odorless

can not be ddetectedwithout specialized equipment -

Highly light

rises and can accumulate in unwell ventilate upper areas

A concentration of simply 4 % hydrogen in air create an explosive mixture that can be ignited by a small spark, open flame, or level static electricity. This is why proper ventilation is essential when charge batteries, and why spark or open flames should ne’er be present near batteries, specially during charge.

Oxygen gas production

Along with hydrogen,

Oxygen (oof)

Is to produce during the electrolysis process. While not flammable itself, oxygen is a powerful oxidizer that enhance combustion and make the hydrogen gas mixture yet more dangerous. The combination of hydrogen and oxygen gases create aaspecially volatile mixture similar to the fuel use in rocket engines.

Battery gas production scenarios

Gas production from automotive batteries occur mainly in these situations:

-

During charge

particularly rapid charging or overcharge -

In overheat batteries

heat accelerate chemical reactions and gas production -

In damaged batteries

physical damage can increase unwanted chemical reactions -

During deep discharge

can lead to ssalvationand increase gas production when recharge

Modern sealed or maintenance free batteries are design to recombine these gases internally, reduce (but not eliminate )the risk. Yet, excessive charging, peculiarly overcharging, can however produce more gas than these systems can recombine, lead to venting and potential hazards.

Source: automotivean.com

Battery safety precautions

Understand the hazard classification and gas emission properties of automotive batteries highlight the importance of proper safety measures:

Handling and transportation safety

- Invariably wear appropriate personal protective equipment (pPPE)when handle batteries, include acacid-resistantloves and eye protection

- Transport batteries vertical and secure them to prevent tipping or damage

- Ne’er allow metal tools to contact both terminals simultaneously

- Keep batteries off from children and untrained personnel

Charge safety

- Charge batteries exclusively in swell ventilate areas

- Keep all ignition sources (sparks, flames, cigarettes )off from charge batteries

- Use proper charging equipment with appropriate voltage and current settings

- Disconnect the charger before disconnect the battery cables

- Ne’er lean straightaway over a battery while connect, disconnecting, or charge

Emergency response for battery incidents

In case of battery relate emergencies:

-

Acid contact with skin or eyes

purge instantly with clean water for astatine least 15 minutes and seek medical attention -

Battery fire

use a class aABCor bc fire extinguisher, ne’er water -

Leak battery

neutralize acid with bake soda and dispose of decent as hazardous waste

Environmental considerations and proper disposal

Due to their hazard classification and toxic components, automotive batteries require special disposal considerations:

- Ne’er dispose of automotive batteries in regular trash

- Recycle batteries through authorize collection centers, auto parts stores, or hazardous waste facilities

- Most automotive batteries are 97 99 % recyclable, with components reuse in manufacture new batteries

- Many retailers offer recycling incentives or core credits when purchase new batteries

Alternative battery technologies and their hazard classifications

While traditional lead acid batteries remain common, alternative battery technologies are progressively use in automotive applications:

Absorbed glass mat (aAGM)batteries

Static classify as hazard class 8 (corrosive ) but with reduced risk of acid leakage. These batteries however produce hydrogen and oxygen gases but typically at lower rates than flood lead acid batteries.

Lithium-ion batteries

Use in electric and hybrid vehicles, these fall under

Hazard class 9 (miscellaneous dangerous goods )

. Their primary hazards include:

- Thermal runaway potential lead to fires

- Release of toxic fluoride gases if damage or burn

- Electrical energy storage hazards

Unlike lead acid batteries, lithium-ion batteries do not produce hydrogen gas but present their own unique set of hazards require specialized safety protocols.

Regulatory requirements for automotive batteries

Due to their hazard classification, automotive batteries are subject to various regulations:

- Transportation regulations under dot and international agreements

- Workplace handling requirements under OSHA standards

- Environmental regulations govern disposal and recycling

- Labeling requirements indicate corrosive hazards

These regulations help ensure proper handling throughout the battery lifecycle, from manufacture to disposal.

Battery safety in vehicle maintenance

For vehicle owners and mechanics, understand battery hazards is essential during routine maintenance:

- Disconnect the negative terminal get go when remove a battery

- Connect the positive terminal start when install a battery

- Ensure proper ventilation when work on vehicle electrical systems

- Keep jump start procedures safe by connect in the proper sequence

- Regularly inspect batteries for damage, leakage, or excessive corrosion

Conclusion

Automotive batteries, while essential for vehicle operation, are classified as class 8 corrosive materials due to their sulfuric acid content. They besides present explosion hazard through the production of hydrogen and oxygen gases, specially during charge. Understand these hazard classifications and the properties of battery produce gases is critical for safe handling, proper storage, and appropriate emergency response.

By follow establish safety protocols and regulatory guidelines, the risks associate with automotive batteries can be efficaciously managed. Proper disposal and recycle not solely protect handlers from corrosive and explosive hazards but besides prevent environmental contamination from toxic lead components.

Whether work with traditional lead acid batteries or newer technologies, safety awareness and appropriate precautions remain essential for anyone handle these powerful but potentially dangerous energy storage devices.

MORE FROM promospotlight.com