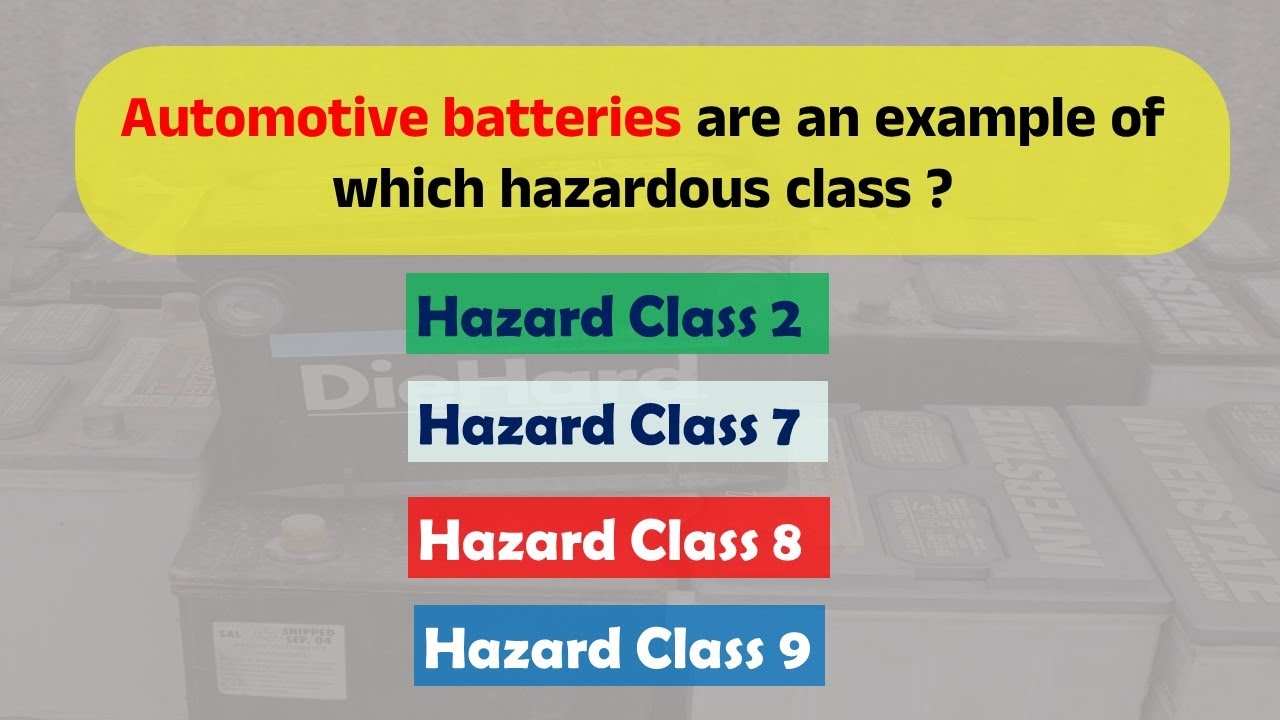

Automotive Batteries: Understanding Their Hazard Classification

Automotive batteries and hazard classification

Automotive batteries are classified as class 8 corrosive materials in the hazardous materials classification system. This classification is crucial for understanding the proper handling, transportation, and disposal of these essential but potentially dangerous components. The corrosive nature of automotive batteries stem from the sulfuric acid electrolyte solution they contain, which can cause severe damage to human tissue, metal surfaces, and the environment if not decent manage.

What make automotive batteries hazardous?

The primary hazard in automotive batteries comes from their chemical composition. Most conventional automotive batteries are lead acid batteries contain:

- Sulfuric acid (electrolyte ) tremely corrosive liquid

- Lead plates toxic heavy metal

- Lead oxide toxic compound

- Plastic casing contain the hazardous materials

The sulfuric acid solution in these batteries typically have a concentration between 30 50 %, which is strong adequate to cause severe chemical burns upon contact with skin or eyes. Additionally, when batteries are damage, charge, or improperly handle, they can release hydrogen gas, create an explosion risk in confine spaces.

Class 8 corrosive materials: definition and criteria

Accord to the department of transportation (dot )and the unUnited Nationsglobally harmonized system of classification and labeling of chemicals ( (sGHS)lass 8 materials are substances that cause visible destruction or irreversible alterations to human skin tissue at the site of contact. They may besides badly damage other materials or means of transport.

Corrosive materials are classified base on their ability to:

- Cause full thickness destruction of intact skin tissue

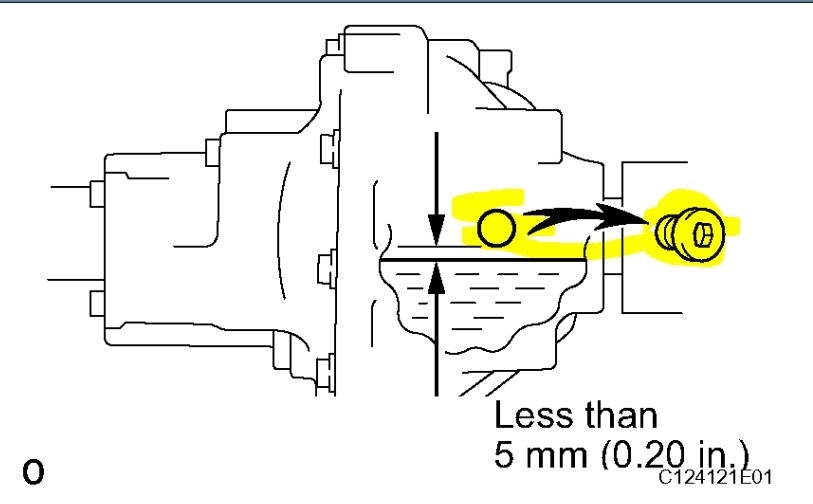

- Exhibit a corrosion rate on steel or aluminum surfaces exceed 6.25 mm per year at a test temperature of 55 ° c

Automotive batteries meet these criteria due to their sulfuric acid content, which can apace damage live tissue and corrode metals.

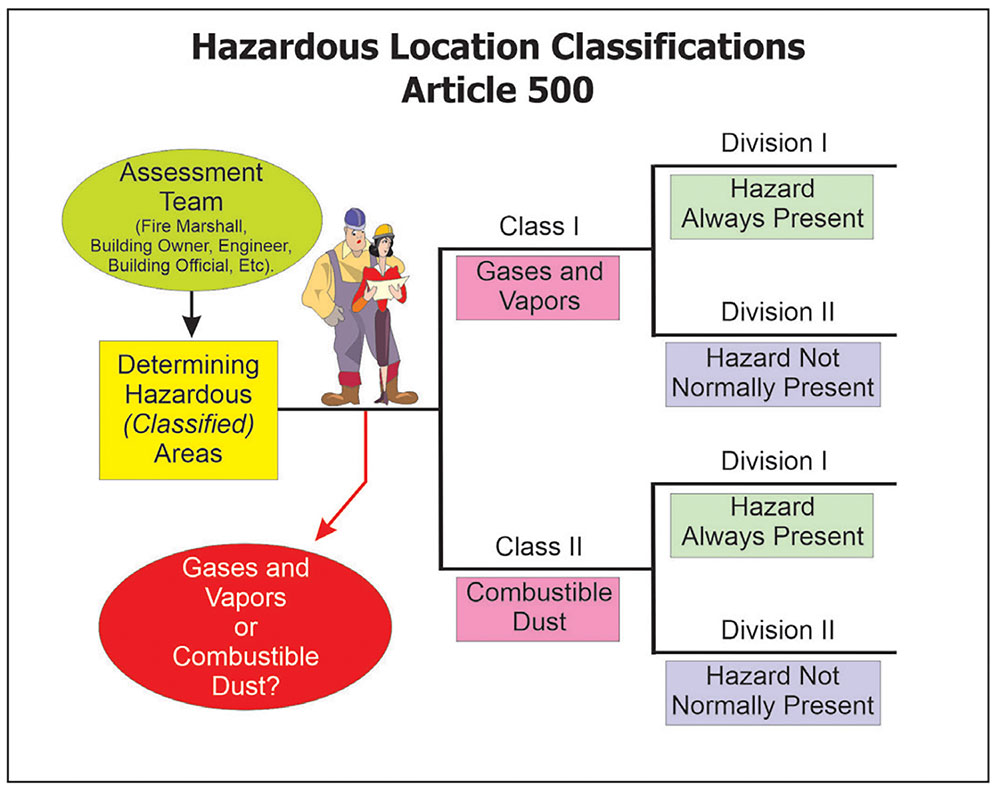

Regulatory framework for automotive battery classification

The classification of automotive batteries as class 8 hazardous materials is consistent across multiple regulatory frameworks:

Department of transportation (dot )

Under dot regulations (49 cCFR) automotive batteries are clclassifieds:

- Un2794 batteries, wet, fill with acid

- Hazard class: 8 (corrosive )

- Packing group: iii (minor danger )

International air transport association (iIATA)

IATA follow similar classification for air transport, with specific packaging instructions for batteries to prevent short circuits and leakage during transport.

International maritime dangerous goods (iIMG))ode

For sea transport, the IMG code tto classifyautomotive batteries as class 8 corrosives with specific stowage and segregation requirements.

Secondary hazard classifications

While the primary hazard class for automotive batteries is class 8 (corrosive ) they may too present secondary hazards:

Environmental hazard

Lead acid batteries contain toxic heavy metals that can cause environmental contamination if improperly dispose of. Many jurisdictions classify use automotive batteries as hazardous waste require special handling.

Potential explosive hazard

During charge or when damaged, batteries can release hydrogen gas, which is flammable and explosive in certain concentrations. This doesn’t change their primary classification but add safety considerations for storage and handling.

Proper handling of class 8 automotive batteries

Understand the hazard classification of automotive batteries inform proper handling procedures:

Personal protective equipment (pPPE)

When handle automotive batteries, appropriate PPE should include:

- Chemical resistant gloves (rubber or neoprene )

- Eye protection (safety goggles or face shield )

- Protective clothing that cover arms and legs

- Apron or other acid-resistant outerwear

Handle precautions

- Keep batteries upright to prevent acid leakage

- Ne’er place metal tools or objects across battery terminals

- Ensure adequate ventilation when charge batteries

- Have neutralized agents( like bake soda) available for acid spills

- Avoid smoking or open flames near batteries

Transportation requirements for automotive batteries

The class 8 designation trigger specific transportation requirements:

Packaging

Automotive batteries must be package to prevent short circuits and contain any potential leakage. This typically include:

- Individual battery terminal protection

- Secure packaging to prevent movement during transport

- Outer packaging capable of contain leak acid

- Upright orientation with appropriate markings

Documentation

Commercial transportation of automotive batteries require:

- Shipping papers identify the hazardous material

- Emergency response information

- Proper marking and labeling of packages

Placard

Vehicles transport large quantities of automotive batteries may require class 8 corrosive placards on all four sides.

Different types of automotive batteries and their classifications

While traditional lead acid batteries are class 8 hazards, the automotive industry has developed alternative battery technologies with different hazard profiles:

Absorbed glass mat (aAGM)batteries

AGM batteries allay contain sulfuric acid but in an absorbed form within fiberglass mats. They remain class 8 hazards but with reduced risk of acid leakage.

Gel cell batteries

These batteries contain sulfuric acid in gel form, which reduce leakage risk but maintain the class 8 classification.

Lithium-ion batteries

Progressively common in electric and hybrid vehicles, lithium-ion batteries present different hazards:

- Primary classification: class 9 (miscellaneous dangerous goods )

-

Un3480 (llithium-ionbatteries )or un3481 ( (tlithium-iontteries contain in equipment )

) - Fire hazard instead than corrosive hazard

Emergency response for automotive battery incidents

The class 8 classification inform emergency response protocols:

Acid spills

For sulfuric acid spill from automotive batteries:

- Evacuate the immediate area

- Neutralize with bake soda, lime, or commercial acid neutralizers

- Avoid direct contact with the acid

- Use absorbent materials to contain the spill

- Dispose of contaminate materials as hazardous waste

First aid for acid exposure

- Skin contact: flush with cool run water for astatine least 15 20 minutes

- Eye contact: flush with water for astatine least 15 20 minutes while hold eyelids open

- Inhalation: move to fresh air

- Ingestion: do not induce vomiting; drink water or milk if conscious

- Seek immediate medical attention for all significant exposures

Disposal considerations base on hazard classification

The class 8 designation affect disposal requirements for automotive batteries:

Regulatory framework

In the United States, use automotive batteries are regulated below:

- Resource conservation and recovery act (rCRA))

- Universal waste rule simplifies management of certain hazardous wastes include batteries

- State specific regulations that may be more stringent than federal requirements

Proper disposal methods

Due to their hazardous classification, automotive batteries should ne’er be disposed of in regular trash. Proper disposal options include:

- Return to retailers (many auto parts stores accept used batteries )

- Recycle facilities specifically equip to handle hazardous materials

- Household hazardous waste collection events

- Manufacturer take back programs

Most automotive batteries are extremely recyclable, with up to 98 % of components recoverable for reuse in new products.

Training requirements for handling class 8 automotive batteries

The hazard classification drive training requirements for those who handle automotive batteries professionally:

Source: kartinausa.info

Harper training

Workers involve in hazardous waste operations may require hazardous waste operations and emergency response (hHarper) )aining under oshaOSHAulations.

Dot hazmat training

Those involve in transport automotive batteries commercially need dot hazardous materials training covering:

- General awareness / familiarization

- Function specific procedures

- Safety training

- Security awareness

Workplace specific training

Automotive repair shops, battery retailers, and recycle facilities should provide training on:

- Safe handling procedures

- Proper storage requirements

- Spill response protocols

- PPE use and maintenance

Compare automotive batteries to other hazard classes

Understand how automotive batteries compare to other hazard classes provide context for their relative dangers:

Class 1: explosives

While automotive batteries can produce hydrogen gas that’s explosive in certain conditions, they don’t meet the criteria for class 1 materials, which have explosion as their primary hazard.

Class 3: flammable liquids

The sulfuric acid in automotive batteries isn’t flammable. This contrast with automotive fluids like gasoline and some solvents that fall under class 3.

Source: fromhungertohope.com

Class 6: toxic substances

Though lead in batteries is toxic, the primary hazard classification remain class 8 due to the immediate danger from the corrosive acid.

Class 9: miscellaneous dangerous goods

This is the classification for lithium-ion automotive batteries, which present different hazards than traditional lead acid batteries.

Global harmonization of automotive battery hazard classification

Hazard classification systems have been progressively standardize internationally:

GHS implementation

The globally harmonized system of classification and labeling of chemicals (gGHS)has ststandardizedazard communication wworldwide Under ghGHSautomotive batteries typically receive these classifications:

- Skin corrosion: category 1a

- Serious eye damage: category 1

- Specific target organ toxicity (lead content ) category 2

- Reproductive toxicity (lead content ) category 1a

International transport regulations

Most international regulations align with the un recommendations on the transport of dangerous goods, which classify automotive batteries as class 8 corrosives.

Conclusion

Automotive batteries are classified as class 8 corrosive materials due to their sulfuric acid content, which can cause severe damage to human tissue and other materials. This classification drive specific requirements for handling, transportation, emergency response, and disposal.

Understand the hazard classification of automotive batteries is essential for anyone who handle these common but potentially dangerous items. From automotive professionals to everyday vehicle owners, proper knowledge of the hazards associate with batteries help prevent injuries, environmental contamination, and regulatory violations.

As battery technology evolve, with more vehicles use lithium-ion and other alternative batteries, hazard classifications may change, but the fundamental principle remains: proper identification and management of hazards are essential for safety in all aspects of automotive battery handling.

MORE FROM promospotlight.com